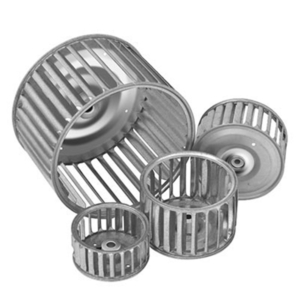

Furnace blower wheels are an important component of furnaces and other heating systems. They are responsible for circulating hot air generated by the furnace throughout the home via ducts. Blower wheels are designed to move air efficiently, and they are typically made from metal or plastic. They are attached to the shaft of furnace’s motor using bolts, screws, or rivets.

How does a furnace blower wheel work?

A furnace blower wheel is a fan-like device that is used to move hot air in a ducted system. It is attached to the shaft of the blower motor which when switched on causes the blades to start running. The rotation of the blades helps the blower fan to create a wind force which then moves the air around the system.

Some furnace blower wheels are also fitted with sensors that can detect whether there is any obstruction within the duct. In such a case, the blower wheel will automatically stop turning. This helps to prevent any damage to the furnace.

Table of Contents

ToggleWhat is furnace blower wheel used for?

As the name suggests, the main job of the furnace blower wheel is to blow hot air via ducts from the furnace into the room. When a natural gas furnace or an electric furnace is turned on, it generates heat in the heat exchanger and produces warm air. But without any additional means of propulsion, that air will remain stationary in the heat chamber and can’t reach the ducts. So, there has to be a system which can drive that warm air produced to the target area.

This is where the furnace blower wheel comes into the picture. It helps the warm air generated by the heat exchanger to get into the ducts by blowing it with required force. Once the warm air gets into the ducts, it will then be released into the rooms to make your home warm. The blower wheel is basically a large fan that uses air flow to push the heated air around. By rotating the blower wheel, it is possible to direct the air in a variety of directions.

Note: The motor of the furnace blower wheel is single speed; it will run at full power until the temperature set by the thermostat is achieved. After that, it will shut off. On the other hand, if it is variable speed motor, it will adjust itself to run at different speeds depending on the pre-set temperature, which helps conserve energy. ̣̣̣̣̣̣

Furnace blower wheel material types

Furnace blower wheels are typically made from a variety of materials, including steel, plastic, aluminum, and bronze. Steel is the most common material used for furnace blower wheels because it is strong and durable.

- Steel furnace blower wheel: Steel is the most common material used in making furnace blower wheels because it is strong and durable. It can withstand the wear and tear of regular use. A steel wheel will also heat up quickly, making it ideal for high-powered furnaces.

- Plastic furnace blower wheel: Plastic is another common material used in making furnace blower wheels. It is light and durable, which makes it perfect for use in small furnaces. Plastic also heats up quickly, making it an ideal choice for high-powered furnaces.

- Aluminum and Bronze furnace blower wheels: Aluminum and bronze are also popularly used in manufacturing furnace blower wheels. Both of them are lightweight and durable, which makes them ideal for use in small furnaces as well as high-powered furnaces.

Note: If you are looking for a furnace blower wheel that is made from a specific material, be sure to check the specifications of the wheel before making your purchase.

Different types of furnace blower wheels

There are various types of furnace blower wheels available and each one of them has its own application. Some of them are mentioned below:

- Forward Curve: When it comes to moving big quantities of air at lesser pressures, multi-vane blower wheels are the way to go. In most cases, slower fan speeds are preferred for general circulation or for applying a cooling force.

- Shrouded Radial Blade: Radial Blade blower wheels with shrouds are ideal for applications that require higher pressures, such as pressurization, blow-off systems, and long-distance ducts or pipes.

- Open Radial Blade with Back Plate: Back Plate blower wheels are used in applications that require lower pressure, such as heating and ventilation systems.

- Convex Radial Blade: Convex Radial Blade blower wheels are a hybrid between the open radial blade and the shrouded radial blade. They offer good performance in both high-pressure and low-pressure applications.

- Airfoil wheels: Airfoil wheels combine the shape of a propeller blade with the cross – sections of an aviation wing. They have the best design for transporting vast amounts of air and are the most productive. They are frequently utilised for ventilation, pressured cooling at greater pressures, and on dust collecting systems.

There are many other types of blower wheels available on the market, but these are some of the most popular ones. It is important to choose the right one for your specific application, in order to get the best performance. If you have any questions about blower wheels, or if you need help finding the right one for your needs, please don’t hesitate to contact us. We would be happy to help you out.

Which way does a furnace blower wheel spin?

A furnace blower wheel can spin in both clockwise and anti-clockwise directions. However, most furnaces are laid on the ground and the air pipes protrude upwards and connect with the ducts that are spread throughout your home.

So, in general cases, it would be safe to say that a furnace blower wheel will typically spin in a counterclockwise direction when viewed from the front of the furnace. This is because the blades of the wheel are angled such that when the wheel spins, the air is pushed outwards and upwards. The opposite is true when viewed from the back of the furnace.

Best furnace blower wheel manufacturer in China

Not exaggerating, but TSL Blower is in fact one of the leading manufacturers of furnace blower wheels in china. We not only pioneer in furnace blowers, but also in all kind of blowers wheels that are used for commercial and industrial purposes. We are unparalleled as far as designing and manufacturing custom-made centrifugal fans and all sizes of blower wheels.

There is no minimum or maximum number of units you can purchase. You just let us know your requirements and we will send your order to your doorsteps, even if it is single piece. We pride in the work we do and never compromise on quality. At TSL Blower every employee is geared towards customer satisfaction, and this, you will know when you get into contact with us.

Since TSL Blower was founded in 2005, we have been continuously striving for innovative designs that meet our customer’s expectations so they can increase their productivity. It’s no wonder that today TSL has become a leader in manufacturing all kinds of blower wheels, especially, in the production of fan impellers and DC fans.

Conclusion

If you are looking for high quality furnace blower wheels as well as a variety of other related products, TSL Blower should be your go-to shop. TSL has years of experience in the blower wheel industry and provides customers with the best possible products at competitive prices.

TSL Blower offers a wide variety of furnace blower wheels to choose from, including both standard and custom sizes. You can also find wheels for gas, electric, and oil furnaces, as well as models tailored for specific applications.

We offer the most outstanding products, as well as unparalleled customer service and support – so why wait? Make the most of our offerings today!

For all your blower wheel needs, get in touch with TSL Blower! Simply give us a call at +86 15899900774 or fill out the form on our website, and one of our representatives will be happy to help you. You can also email us at jaron@tslindustry.com and we will reply within 24 hours. We look forward to helping you find the perfect wheel for your needs! Thank you for choosing TSL Blower!

FAQs about furnace blower wheel

What material is good for a furnace blower wheel?

The best material for a furnace blower wheel is steel because it is strong and durable. However, other materials can also be used if they are strong enough. Some other factors to consider when choosing a material for a furnace blower wheel are the cost and how easy it is to handle.

How often should I clean my furnace blower wheel?

You should clean your furnace blower wheel every two to four months. Cleaning the wheel helps it run smoother and prevents debris from accumulating, which can clog the fan and cause the furnace to overheat. You can use a vacuum cleaner to clean the wheel, or you can use a hose and bucket. Make sure to wear gloves and eye protection when cleaning the wheel.

What are some things to avoid when cleaning my furnace blower wheel?

When cleaning your furnace blower wheel, be careful not to damage it. Avoid using harsh chemicals or cleaners, which can damage the wheel. Also, avoid touching the fan blades with your hands.