Custom Blower Wheel Manufacturing

Our rigorous quality control measures are designed to guarantee that all TSLblower products not only meet but exceed industry standards, ensuring reliability and customer satisfaction.

Metal Sheet Processing at TSLblower

Laser Cutting:

At TSLblower, we employ state-of-the-art laser cutting machines to precisely measure and cut workpieces, ensuring high-quality finished products and efficient production.

Stamping:

Our stamping process utilizes modern techniques and a ton hydraulic press to create robust components such as air inlets, blower impeller rings, and fan blades. Precision stamping machines operated by skilled workers allow for meticulous attention to detail, particularly with smaller components.

Welding:

We implement advanced automatic welding technology. Experienced technicians utilize subarc welding to expertly join housings and impellers, processing materials including mild steel, stainless steel, and aluminum alloy.

Assembling:

Our assembly line features automated blower blade assembly technology, enhancing both efficiency and speed in production.

Testing:

To ensure the highest standards of performance and quality, we conduct a variety of tests:

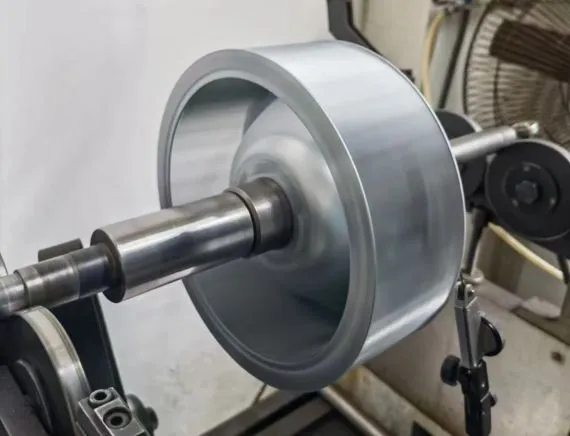

- Fan blade balancing

- Fan assembly balancing

- Air duct testing

- Wind tunnel testing

- High-temperature testing