A blower wheel is the component of warming and conditioning system that is responsible for bringing conditioned airflow from the home’s furnace, heating system, or air conditioner into the living space.

After heating or cooling the air, the system’s blower wheel propels it through the duct circuit and releases it through vents in every room of your residence or office.

A blower increases the speed of air or gas as it moves through impellers attached to the blower, making it either a piece of equipment or a device.

Its primary function is to allow the movement of air or gas that is necessary for various processes such as exhausting, aspirating, chilling, ventilating, conveying, etc. In the manufacturing world, blowers are also frequently referred to as centrifugal fans.

When it comes to blower, the force at the outlet is significantly higher than the force at the entrance. The speed of the blades contributes to a rise in the air’s tension just before it exits the vent.

Blowers are most commonly utilised in industrial settings for moderate force requirements. In these settings, the pressure must be greater than that of a fan but lower than that of a compressor.

Table of Contents

ToggleWhat Is a Blower Wheel Used for?

Without the aid of a proper blower wheel, your air-conditioning, ventilation, as well as heating device will not function effectively. These HVAC devices utilize blowers and fans to rotate the air, making them a crucial component of the air handling equipment that brings fresher air into the structure or residence.

If you’re using blowers for ventilation, install them inside a ducting system or on an outside wall. Blowers operate electrically to generate unidirectional airflow for pre-heated or pre-cooled air.

The most important of the components that make up a blower is blower wheel. The blower motor and its robust outer coating guard the central disc as well as the fan mechanism.

Most of the time, blower wheels are manufactured out of cold-rolled galvanised steel, which is resistant to rust as well as corrosion. Because of its meticulous construction, the performance you get will be strong and long-lasting for many years ahead.

Despite the fact that several blower wheels have a temperature rating of up to 200 degrees Fahrenheit, the optimal temperature range for their operation is somewhere between 130- and 200-degrees Fahrenheit.

Blower wheels commonly feature in fans, primarily generating vast volumes of air at low pressures. They actively compel the air to exit the fan parallel to its width.

A pre-tooled plastic impeller mold can produce plastic blower wheels or customize them to match the exact specifications provided by the customer. Making use of the “Pre-tooled” method helps save both time and money during the mould development process.

This drastically reduces the time between placing the order and delivering the specific parts.

Blower Wheels provide your fans with outstanding performance while reducing the amount of noise they produce. They help to draw air into or expel it from a space, practically in every kind of fan.

It includes axial fans, centrifugal fans, as well as exhaust fans, that have a blower attached to it. Drying, chilling, suction, and exhaust activities are all examples of applications for the Blower Wheel.

Blower Wheel Material Types

Materials for the fan have a significant role in both the design and production processes of centrifugal fans. The mass, cost, cleanliness, durability, maintainability, and aesthetic of a building can all be impacted by the materials used in its construction.

When it comes to construction of the fan wheel, accessories, or even the full fan, there are diverse options of materials to select from. TSL Blower carries the suitable and greatest materials for your application, regardless of whether it requires rising operating temperatures, caustic contaminants, and perhaps explosive environments. These materials include:

- All carbon steel grades

- Titanium

- All stainless steels

- Aluminium

- Monel

- Nickel-based alloys (625, C22, C276, etc.)

Blower Wheel Types

The designs of industrial fans are developed to fulfil particular performance criteria while preserving the devices’ structural integrity. Different industrial fans applications have specific flow and pressure requirements.

In various environments, fans serve purposes such as operating at high rotation speeds, enduring corrosive settings, withstanding abrasive air flows, and tolerating extreme temperatures, whether high or low.

These application criteria and the specific surroundings where you plan to deploy them should guide your selection of a suitable fan or blower.

In order to generate enormous volumes of air at low force, fans make use of a combination of fan as well as blower wheels. Via the housing’s outlet, air is expelled in a direction that is perpendicular to the housing.

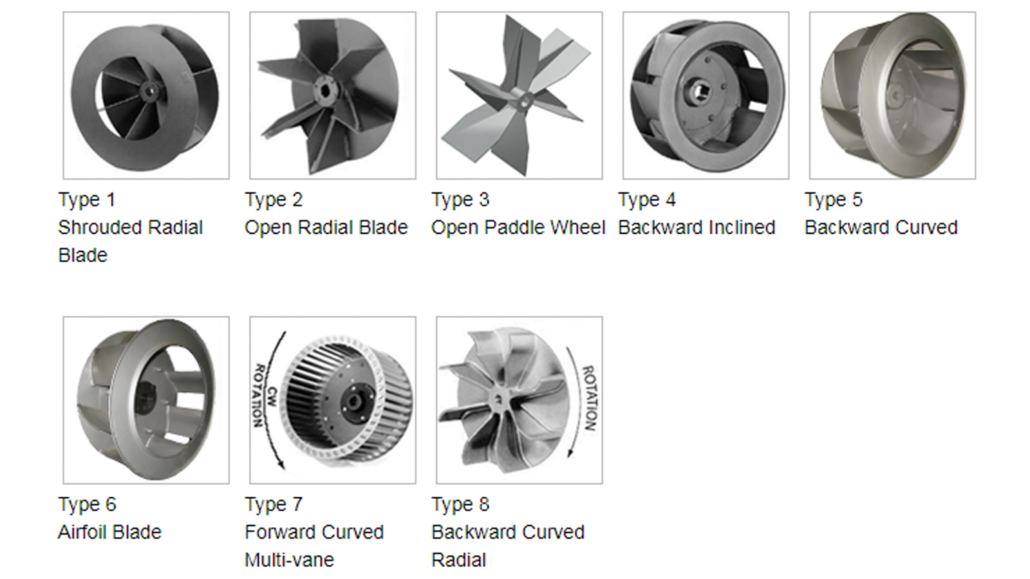

Manufacturers fit Industrial fans and blowers with one of several distinct types of blower motors or centrifugal impellers. Here’s a list of the eight most common types of wheels found in industrial fans and blowers:

Shrouded radial-blade

High-pressure pressurising, blow-off systems, and lengthy duct or pipe lengths are all ideal applications for shrouded radial-blade blower wheels.

Open radial blades and back plates

Blower wheels constructed with open radial blades and back plates can convey the powdered or granular substance and the long, stringy paper trims or fibers. Moving material that is powdery or granular, as well as paper scraps or fibres that are lengthy and stringy.

Open paddle wheel

The primary purpose of the open paddle wheel is the conveyance of granular or powdered materials.

Blower wheel that is tilted backwards

Flat-bladed, backward-angled fan wheels are a thing. Manufacturers often employ these wheels in dust-collecting systems, positioning the fan on the fresh air face of the dust extractor. They also use them for general ventilation and pressurized cooling under higher pressures.

Backward Curved shape

High performance and low noise are provided by blower wheels with a backward-curved shape. Common applications for these fans include general ventilation, dust collecting (with the fan positioned on the clean face of the dust collector), providing combustion air, as well as drying.

Airfoil wheels

Airfoil wheels combine the shape of a propeller blade with the cross – sections of an aviation wing. They have the best design for transporting vast amounts of air and are the most productive.

These versatile systems are essential for a wide variety of applications, including ventilation, high-pressure cooling, and dust collection. Their reliable performance and efficiency make them an excellent choice for any industrial setting. Don’t miss out on the benefits these systems can provide for your business.

Forward Curve

When it comes to moving big quantities of air at lesser pressures, multi-vane blower wheels are the way to go. In most cases, slower fan speeds are preferred for general circulation or for applying a cooling force.

Blower wheel with a radial bend in the opposite direction

You can envision the Opened Radial Blade wheel as a variant called the Backward Curved Radial blower wheel.

Which Way Does a Blower Wheel Spin?

The blower wheel can rotate in either the clockwise or counter clockwise direction, and while it does so, the forward-curving, small blades on the wheel gather up the airflow and fling it out of the device.

It is constructed to move large volumes of airflow while generating a very minimal static pressure. As a result, this layout is ideal for applications such as furnaces or ovens that rely on convective heat and require keeping the temperature consistent throughout the room.

You must choose whether the wheel will operate or spin in a clockwise (CW) or counter clockwise (CCW) cycle direction before purchasing. When it comes to the entire performance as well as air flow properties of a blower wheel, having the correct rotation is one of the most essential and crucial factors.

Reversing the direction of spin of a blower wheel will render the wheel unable to circulate air productively or efficiently.

It has a significant negative impact on performance and has the potential to result in a variety of property as well as equipment damages. It is absolutely necessary to verify and indicate the correct spinning direction of the wheel.

Leading Manufacturer of Blower wheel in China

TSL Blower, with headquarters in China, is an industry-leading maker of centrifugal fans as well as blowers. Our company designed, manufactured, and delivered heavily loaded centrifugal fans and blowers for industrial processes.

We specialise in centrifugal industrial fans, as well as for residential needs, whether it be cooling or heating. We maintain a consistently high level of quality in all our products.

Various industries commonly utilize centrifugal fans to actively move air, gases, and raw materials in production, ultimately yielding a final product.

Centrifugal fans as well as blowers move air and, as a result, act as operatives of change of many different kinds. These changes can occur in the components, the assembly, or the surroundings.

TSL specializes in researching and innovating DC blower fans and impellers. 2005 marked the beginning of TSL’s operations.

Based on years’ worth of experience in the production of plastic injection moulds and components, TSL has become a leader in manufacturing all kinds of blower wheels. TSL is a leading manufacturer of fan impellers and DC fans

Conclusion

You may find the best deal on blower wheels as well as a wide variety of other variants and accessories when you shop at TSL Blower. TSL has extensive experience in the industry, unrivaled by any other.

We not only provide you with the best products but also with customer service and support that is unmatchable.

So, what are you waiting for? Just give us a call or fill in the form on our website and one of our representatives will call you! Contact TSL Blower today for all your blower wheel needs!!