When designing any air-moving system, from a compact kitchen extractor fan to a massive commercial air handling unit, engineers face a fundamental design choice that has ripple effects throughout the entire project: should the blower wheel have a single inlet or a double inlet? On the surface, it might seem like a minor detail, but this decision is one of the most critical you’ll make. It dictates the fan’s performance capabilities, its physical footprint, its efficiency, and even its cost. Choosing the right configuration is the difference between a system that runs quietly and efficiently and one that is oversized, underpowered, or struggles to meet performance targets. It’s a classic engineering trade-off between power and volume, pressure and space.

The choice between a single-inlet and double-inlet blower wheel depends on your primary need: single-inlets excel at creating high pressure for systems with significant resistance, while double-inlets are unmatched for moving large volumes of air in more open systems. Your application’s specific airflow (CFM) and static pressure requirements will dictate the correct design.

Imagine you’re tasked with two different projects. The first is a dust collection system that needs to pull sawdust through long, narrow ducts—a high-pressure job. The second is a ventilation system for a large warehouse that needs to circulate a huge volume of air—a high-airflow job. The hero of both stories is the blower wheel, but you can’t cast the same actor for both roles. One requires a specialist in generating force, the other a master of moving mass. This guide will explore the unique strengths and weaknesses of both single-inlet and double-inlet designs, helping you make an informed choice that ensures your system performs exactly as intended.

Table of Contents

ToggleIntroduction

What Are Blower Wheels?

Before diving into the specifics of inlet design, let’s start with the basics. A blower wheel, also known as an impeller or fan wheel, is the rotating heart of a centrifugal fan. It’s the component that actually does the work of moving air. As the wheel spins, its blades draw air into the center and then accelerate it outwards using centrifugal force. This process generates both airflow (the volume of air moved) and pressure (the force used to move it). They are essential components in a vast range of applications, from the HVAC system that keeps your office comfortable, to the industrial oven that bakes your bread, to the specialized fume hood that keeps a laboratory safe.

Why Does Inlet Type Matter?

The “inlet” is the opening where air enters the blower wheel. The choice between having one inlet (single-inlet) or two (double-inlet) is a fundamental design decision that defines the fan’s entire character. It’s not just a cosmetic difference; it directly impacts:

- Performance: It determines the fan’s natural aptitude for producing either high pressure or high airflow.

- Efficiency: The right inlet configuration for the job ensures the fan operates near its peak efficiency, saving energy.

- Physical Footprint: The number of inlets dictates the shape and size of the fan housing and the overall system.

- System Design: It influences how ductwork is connected and how the fan is mounted and supported.

In short, choosing the correct inlet type is the first step in matching the fan’s capabilities to the demands of your specific application.

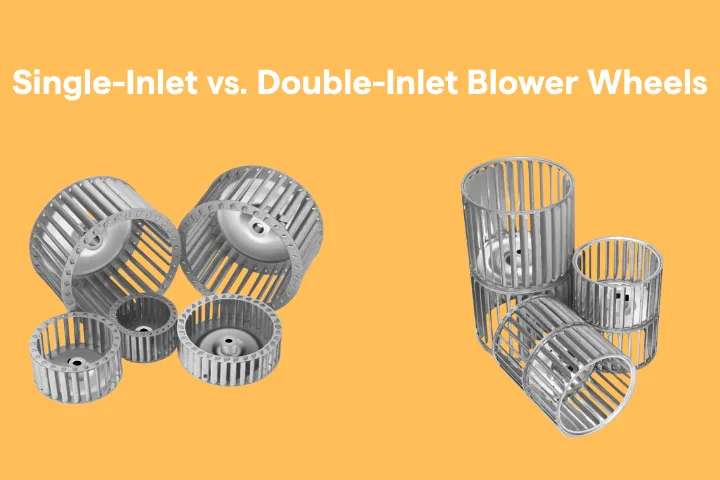

What is a Single-Inlet Blower Wheel?

A single-inlet blower wheel, often designated as SISW (Single Inlet, Single Width), is a design where air is drawn into the fan from only one side. This configuration is typically enclosed in a scroll-shaped housing (a volute) that efficiently channels the discharged air into a single outlet duct. Its design is inherently focused on converting the velocity of the air into high static pressure, making it a specialist in overcoming resistance.

Design and Functionality

The key to the single-inlet design is its partnership with the volute housing. Air enters through the single opening, is accelerated by the blades, and then thrown outwards into the progressively expanding scroll housing. This housing design is crucial; it slows the air down in a controlled manner, which converts the air’s kinetic energy (velocity pressure) into potential energy (static pressure). Think of it like a nozzle on a hose working in reverse. Instead of speeding water up into a jet, it’s taking fast-moving air and building up force.

Mechanically, the wheel is often “overhung,” meaning it’s mounted on the end of the motor shaft with support on only one side. This makes for a compact and simple arrangement that is easy to integrate into various types of equipment.

Common Applications

You’ll find single-inlet blowers in any application where the primary challenge is pushing or pulling air through a restrictive system. Their ability to build pressure makes them indispensable for:

- High-Pressure Industrial Ventilation: Systems with long, complex duct runs, filters, and dampers that create significant resistance.

- Dust Collection Systems: Pulling heavy particulate matter like sawdust or metal shavings through a network of ducts and into a collector requires immense suction (negative pressure).

- Fume and Chemical Extraction: Laboratory fume hoods and industrial chemical exhaust systems need powerful fans to ensure hazardous fumes are safely captured and vented.

- Material Conveying: Using air to move light materials like grains, plastic pellets, or powders from one point to another.

- High-Performance Ovens: Ensuring hot air is forcefully circulated throughout an oven chamber to guarantee even heating and cooking.

Key Benefits

What is a Double-Inlet Blower Wheel?

A double-inlet blower wheel, known as DIDW (Double Inlet, Double Width), is a design that features two inlets, allowing it to draw air from both sides simultaneously. It’s essentially two single-inlet wheels placed back-to-back and sharing a common backplate. This configuration is a master of moving large volumes of air and is typically housed in a simpler, more open enclosure or used as a plenum fan without a traditional volute.

Design and Functionality

The core principle of the double-inlet design is maximizing airflow (CFM) for a given wheel diameter. By drawing air from two sides, it can move nearly twice the volume of air as a single-inlet wheel of the same diameter and speed. This makes it incredibly efficient in terms of space for high-volume applications.

Mechanically, the DIDW arrangement is different. The wheel is typically mounted with the shaft passing through its center, supported by bearings on both sides of the fan housing. This “supported-on-both-sides” configuration provides excellent stability, which is crucial for the wider, heavier wheels. While they can be placed in a scroll housing, they are very often used as unhoused “plenum” fans, discharging air into a large chamber (the plenum), which then distributes the air to multiple ducts.

Common Applications

Double-inlet blowers are the go-to choice when the goal is to move a massive amount of air in systems with relatively low resistance. Their applications are widespread:

- Commercial HVAC Air Handling Units (AHUs): These are the large units on the roofs of office buildings, malls, and hospitals responsible for circulating conditioned air throughout the entire building.

- Large-Scale Ventilation: General ventilation for large open spaces like warehouses, factories, and parking garages where air exchange is the primary goal.

- Plenum Fans: Used in modern air handling systems where the fan pressurizes a large box (plenum), from which air is then distributed. This is a very efficient and quiet design.

- Air Curtains: Creating a broad, high-volume sheet of air to separate a conditioned indoor space from the outside environment.

Key Benefits

How Do They Differ in Performance?

The performance differences are stark and define their roles. A single-inlet fan is a high-pressure specialist, while a double-inlet fan is a high-volume champion. This distinction arises directly from their design, affecting not just airflow and pressure but also their efficiency in different scenarios and their physical space requirements. Understanding this trade-off is key to selecting the right fan for the job.

Airflow and Pressure

This is the most fundamental difference.

- Single-Inlet (SISI): Generates high static pressure but moves a lower volume of air. The volute housing is critical for this pressure conversion. It’s designed to fight against resistance.

- Double-Inlet (DIDI): Moves a very high volume of air (nearly 2x that of a SISI wheel of the same diameter) but is less effective at building high static pressure. It’s designed for free-flowing air movement.

A Simple Rule of Thumb: If your system has long ducts, filters, and lots of bends (high resistance), you need the pressure of a single-inlet. If you need to ventilate a large, open space with minimal ducting (low resistance), you need the volume of a double-inlet.

Efficiency Considerations

A fan’s efficiency is highly dependent on its blade type and operating point, but the inlet configuration plays a role.

- Blade Type is Key: In both single and double-inlet configurations, a backward-curved or airfoil blade design will always be more energy-efficient than a forward-curved design. This is the most important factor for energy consumption.

- Matching to the Application: True efficiency comes from matching the fan type to the job. Using a high-volume double-inlet fan in a high-pressure application would be incredibly inefficient, as it would be operating far from its Best Efficiency Point (BEP). Conversely, using a single-inlet fan where high volume is needed would require a much larger, more powerful, and less efficient fan than a properly sized double-inlet model.

Size and Space Requirements

The physical footprint is a major practical consideration. While it seems counterintuitive, the “bigger” double-inlet fan can sometimes be the more space-efficient choice.

| Factor | Single-Inlet (SISW) | Double-Inlet (DIDW) |

|---|---|---|

| Primary Strength | High Pressure | High Airflow Volume |

| Footprint Shape | Typically narrower but can be taller due to the volute housing. | Wider due to the double-width wheel, but often more compact in height (especially in plenum setups). |

| Space Efficiency | More space-efficient for generating high pressure. | More space-efficient for generating high airflow volume. |

| Typical Mounting | Overhung (supported on one side). | Supported on both sides. |

Which Applications Suit Each Type?

The best way to understand the difference is to see where each type shines. The choice is dictated by the specific demands of the system. A single-inlet fan is a specialist for overcoming resistance, while a double-inlet fan is a powerhouse for moving large quantities of air with ease. Selecting the right one ensures optimal performance and efficiency.

Single-Inlet Use Cases: The Pressure Specialists

Think of any system where the air has to be forced through a challenging path. That’s where you’ll find a single-inlet fan.

- Compact Electronics Cooling: In servers or telecom equipment, a small single-inlet blower can generate the focused pressure needed to force cooling air through densely packed components and heat sinks.

- Residential and Commercial Ovens: Convection ovens rely on a single-inlet fan to forcefully circulate hot air, ensuring that heat penetrates food evenly and overcomes the resistance of racks and trays.

- Air Purifiers and Vacuum Cleaners: These devices must pull air through dense HEPA filters or create strong suction. This is a classic high-pressure, lower-airflow task perfectly suited for a single-inlet design.

- Process Drying: In industrial settings, single-inlet blowers provide the high-velocity, high-pressure air needed to blow off water or dry coatings on a production line.

Double-Inlet Use Cases: The Volume Kings

Think of any application where the goal is to condition or replace the air in a large space.

- Commercial Air Handling Units (AHUs): The workhorses of commercial HVAC, these units use large double-inlet blowers to draw in outside air, pass it over heating/cooling coils and through filters, and then distribute massive volumes of conditioned air throughout a building.

- Factory and Warehouse Ventilation: To maintain air quality and temperature in a vast, open factory, you need to move an enormous amount of air. A double-inlet fan is the most efficient way to achieve the required air changes per hour.

- Paint Booth Exhaust: While some booths require high pressure, many large-scale paint booths prioritize moving a high volume of air to quickly clear overspray and solvent fumes, making a double-inlet fan an ideal choice.

Customization Options: When Off-the-Shelf Isn’t Enough

While these are general guidelines, many real-world applications fall somewhere in between. Your product might need a unique balance of pressure and airflow that a standard model can’t provide efficiently. This is where customization becomes critical.

An experienced manufacturer like TSLBlower doesn’t just offer a catalog of standard parts. We work with you to engineer a solution. We can modify blade angles, adjust wheel widths, and select specific materials to create a custom single-inlet or double-inlet wheel that perfectly matches your product’s unique performance curve, ensuring maximum efficiency and reliability.

What Are the Cost and Installation Factors?

Beyond pure performance, practical considerations like cost, installation complexity, and maintenance play a huge role in the decision-making process. A single-inlet fan is generally less expensive upfront and simpler to install in ducted systems. However, a double-inlet fan, while more complex, can be the more cost-effective choice for high-volume applications when considering the total system size and energy consumption.

Cost Comparison

The initial purchase price is often a primary driver.

- Single-Inlet Fans: Tend to have a lower upfront cost. The wheel itself is simpler (single width), and the overhung design can be less complex to manufacture. For applications where a single-inlet fan is the right performance choice, it’s usually the more economical one.

- Double-Inlet Fans: Are typically more expensive. The wheel is wider and more complex, and the “supported-on-both-sides” bearing arrangement adds cost and complexity to the housing. However, if you need high airflow, trying to achieve it with a massive single-inlet fan would be far more expensive than using a moderately sized double-inlet fan.

Installation Complexity

How the fan integrates into your system can have a big impact on labor and material costs.

- Single-Inlet Fans: Installation is often more straightforward, especially in systems with clear, single-path ductwork. There is one inlet and one outlet to connect. The primary challenge is ensuring the overhung motor and wheel assembly is properly supported to handle the cantilevered load.

- Double-Inlet Fans: Installation can be more complex. You must ensure that air can flow freely and evenly to *both* inlets. Obstructing one side will starve the fan, unbalance the airflow, and severely degrade performance. This requires careful planning of the surrounding enclosure or plenum.

Maintenance Requirements

Long-term serviceability is another key factor.

- Single-Inlet Fans: In an overhung arrangement, the motor and drive components (if belt-driven) are often more exposed and easier to access for routine maintenance like lubrication or belt tensioning.

- Double-Inlet Fans: The bearings are typically located on either side of the housing. Depending on the enclosure design, accessing both bearings for maintenance can sometimes be more challenging. Regular cleaning is also critical to prevent uneven buildup on the wider wheel, which can cause imbalance.

Single-Inlet vs. Double-Inlet Blower Wheel: How to Make the Right Choice?

Making the right choice comes down to a systematic evaluation of your project’s specific needs. By clearly defining your performance requirements and system constraints, you can confidently select the configuration that offers the best balance of performance, efficiency, and cost. It’s a process of asking the right questions before you commit to a design.

Evaluating Your Needs: A Checklist

Before you consult a catalog or speak to a supplier, answer these core questions about your application:

1. What is my primary goal: Pressure or Airflow?

If you need to overcome high resistance (long ducts, filters), start by looking at single-inlet fans. If you need to move a large volume of air in an open system, your starting point should be double-inlet fans.

2. What are my exact performance numbers?

Define your target duty point: “I need to move X CFM at Y inches of static pressure.” This is the single most important piece of data you need.

3. What are my space constraints?

Measure the physical space (height, width, depth) available for the fan unit. Will a narrower, taller single-inlet unit fit better, or a wider, shorter double-inlet unit?

4. What is my budget?

Consider both the initial purchase price and the long-term operating cost. A more efficient fan might cost more upfront but save you money on electricity bills over its lifespan.

Consulting Experts

Once you have this data, the next step is to talk to an expert. An experienced blower wheel supplier can provide invaluable guidance that you won’t find on a spec sheet.

Working with a manufacturer like TSLBlower gives you access to engineers who live and breathe this technology. We can look at your requirements and not only recommend the right inlet type but also suggest custom modifications that could improve performance or reduce cost. This collaborative approach ensures you get a solution that is truly optimized for your needs, not just a part that is “close enough.”

Considering Certifications

Finally, never overlook the importance of quality and safety certifications. A reliable product is backed by proof of its quality. Look for suppliers whose products meet recognized international standards. Certifications like CCC, CE, RoHS, and UL are not just logos; they are an assurance that the blower wheel has been tested for safety, material content, and performance. This is your guarantee that the component will be reliable and won’t become a point of failure in your final product.

Conclusion

Key Takeaways

The choice between a single-inlet and a double-inlet blower wheel is a strategic one, dictated by the specific physics of your application. The decision boils down to a simple trade-off:

- Choose a Single-Inlet Blower Wheel when your primary challenge is high pressure. It is the specialist for overcoming resistance in systems with long ducts, filters, or other obstructions.

- Choose a Double-Inlet Blower Wheel when your primary goal is high airflow volume. It is the champion of moving large quantities of air efficiently in low-resistance systems like large-scale HVAC and ventilation.

By correctly identifying your system’s needs for pressure, airflow, and space, you can select the configuration that will deliver optimal performance, efficiency, and long-term value.

Next Steps

Making the right choice is critical, but you don’t have to make it alone. Partnering with a trusted, experienced supplier is the best way to ensure your theoretical design becomes a high-performing reality. At TSLBlower, we combine over two decades of specialized manufacturing expertise with a commitment to custom solutions and rigorous quality control.

Ready to Find the Perfect Blower Wheel?

Whether you need a high-pressure single-inlet for a demanding industrial process or a high-volume double-inlet for a commercial HVAC unit, our team is ready to help. We offer custom design services, rapid prototyping, and a zero-MOQ policy to support your project at any scale.

Contact TSLBlower Today for an Expert Consultation and a Custom Quote