Are your energy bills dominated by the constant hum of blower motors running at full speed? In many industrial and commercial facilities, fans run at 100% capacity even when the system only requires a fraction of that airflow. This is a massive source of wasted energy and money. The solution is the powerful combination of a blower wheel and a Variable Frequency Drive (VFD).

To properly pair a blower wheel with a VFD for maximum efficiency, you must select a structurally robust wheel designed for variable speeds (like a backward-curved impeller), apply the Fan Affinity Laws to calculate energy savings, and program the VFD to avoid hitting the system’s critical speed or resonant frequency.

This might sound complex, but the principles are straightforward, and the rewards are immense. Integrating a VFD is one of the single most effective upgrades you can make to an air movement system. This guide will demystify the process, walking you through the essential science, the practical hardware choices, and the critical steps to ensure your system is not just efficient, but also reliable and safe for the long haul.

Table of Contents

ToggleWhat is a Variable Frequency Drive (VFD) and Why Use It with a Blower?

A Variable Frequency Drive (VFD) is an electronic device that controls the speed of an AC electric motor by adjusting the frequency of the electrical power supplied to it. It is used with a blower to precisely match the fan’s speed to the exact airflow demand of the system, which dramatically reduces energy consumption compared to running the motor at a constant full speed.

Think of a VFD as a sophisticated dimmer switch for a powerful motor. Instead of a simple on/off control, a VFD gives you granular control over the motor’s revolutions per minute (RPM). In a traditional system, if you need 50% airflow, you typically use a mechanical damper—essentially a plate that blocks half the airflow. This is incredibly inefficient. It’s like flooring the gas pedal in your car while also pressing the brake to control your speed. A VFD lets you simply ease off the gas pedal instead.

The Basics of VFDs: Controlling Speed by Adjusting Frequency

An AC motor’s speed is directly tied to the frequency of the electrical power it receives (measured in Hertz, Hz). In North America, standard grid power is 60 Hz. A VFD takes this constant 60 Hz power, converts it, and then outputs a new, adjustable frequency. By sending 30 Hz to the motor, the VFD makes it run at roughly half speed. By sending 45 Hz, it runs at 75% speed. This ability to dial in the exact speed needed is the key to its power.

The Primary Benefit: How VFDs Unlock Massive Energy Savings

The relationship between fan speed and power is not linear; it’s exponential. As we’ll explore in the next section, even a small reduction in speed leads to a huge reduction in power consumption. Because blowers and fans are such common and high-energy consumers in buildings and industrial processes, the potential for savings is enormous. Payback periods for a VFD installation are often just one to two years, making it one of the best ROI projects in facility management.

Beyond Energy: Achieving Better Process Control and Reducing Mechanical Stress

While energy saving is the main driver, VFDs offer other significant benefits. They provide precise and automated control over processes like ventilation rates, drying times, or static pressure. They also act as a “soft starter,” gradually ramping up the motor’s speed instead of slamming it on at full power. This reduces mechanical stress on belts, bearings, and the blower wheel itself, leading to a longer operational life for all components.

Is a VFD Right for Every Blower Application?

While incredibly powerful, VFDs are not a universal solution. They are most effective in systems where the demand for airflow varies significantly throughout the day. For a blower that must run at a constant 100% speed, 24/7, a VFD will not provide significant energy savings. The true value is unlocked in systems with variable loads.

How Do Fan Affinity Laws Govern VFD Performance?

The Fan Affinity Laws are a set of three scientific principles that govern the relationship between a blower’s speed and its performance. They state that airflow is directly proportional to speed, pressure is proportional to the square of the speed, and most importantly, the power required is proportional to the cube of the speed. This “Cube Law” is what allows VFDs to save so much energy.

Understanding these three simple laws is the key to grasping the incredible financial impact of a VFD. They allow you to accurately predict how a fan will perform at different speeds and calculate the potential energy savings with confidence.

Breaking Down the Three Fan Laws

- The First Law (Flow): Airflow is directly proportional to the fan speed. If you reduce the fan speed by 10% (to 90% of its original speed), the airflow also drops by 10% (to 90% of its original volume).

- The Second Law (Pressure): Static pressure is proportional to the square of the fan speed. If you reduce the fan speed to 80%, the pressure drops to (0.80)², or 64% of the original pressure.

- The Third Law (Power): The power required by the fan is proportional to the cube of the fan speed. This is the most important law for energy savings.

The Cube Law in Action: Why Power Drops So Dramatically

Key takeaway: A 20% reduction in fan speed results in a power reduction of nearly 50%.

Let’s apply the Third Law. If you reduce the fan speed to 80% (a 20% reduction), the power required by the motor drops to (0.80)³, which is 0.512. This means the fan only needs 51.2% of the original power to run. You cut the speed by a little, and you cut the energy consumption by a lot. This non-linear relationship is the engine behind VFD savings.

A Practical Example: Calculating Savings for a Speed Reduction

The table below clearly illustrates how these laws work together. Notice how dramatically the power requirement drops off as the speed is reduced.

| Fan Speed | Airflow (CFM) | Static Pressure | Power Required |

|---|---|---|---|

| 100% (Full Speed) | 100% | 100% | 100% |

| 90% Speed | 90% | 81% (0.9²) | 73% (0.9³) |

| 80% Speed | 80% | 64% (0.8²) | 51% (0.8³) |

| 50% Speed | 50% | 25% (0.5²) | 12.5% (0.5³) |

Which Blower Wheel Designs Are Best Suited for VFDs?

Backward-curved blower wheels are generally the best choice for VFD applications due to their high structural integrity, stable performance across a wide range of speeds, and non-overloading power characteristics. While forward-curved wheels can be used, they require more careful system design to prevent motor overload and potential instability at lower speeds.

A VFD places unique stresses on a blower wheel. The ability to operate smoothly across a wide RPM range is critical. Not all wheel designs are equally suited for this task. The construction, balance, and aerodynamic properties of the wheel itself are just as important as the electronic controller.

Why Backward-Curved Wheels Are Often the Superior Choice for VFDs

Backward-curved impellers, especially those with fully welded blades, are inherently more robust. Their blades are designed to withstand the high centrifugal forces of high-speed operation. More importantly, they have a “non-overloading” power curve. This means that as system pressure changes, the horsepower required by the fan reaches a peak and then drops off, which prevents the motor from overloading and tripping the VFD. Their stable, efficient performance makes them a reliable and safe choice for VFDs.

Are Forward-Curved Wheels Compatible with VFDs? Key Considerations

Forward-curved wheels, common in residential and light commercial HVAC, can be used with VFDs, but with caution. They have an “overloading” power curve, meaning the horsepower required can continue to rise if system pressure drops. This requires careful sizing of the motor and VFD to ensure they can handle the maximum potential load without being damaged. They can also be more prone to instability when operated at very low speeds (turndown ratios).

The Critical Role of Structural Integrity and Dynamic Balance for Variable Speeds

Regardless of the design, a blower wheel paired with a VFD must be exceptionally well-built and balanced. A VFD system will likely pass through a wider range of operating speeds, increasing the chance of exciting natural vibrations. Any small imbalance that is barely noticeable at full speed can become a violent, destructive vibration at a lower speed. A high-quality, dynamically balanced wheel is essential for smooth, quiet, and reliable operation.

What is “Critical Speed” and How Do You Avoid It with a VFD?

“Critical speed” is a rotational speed that matches a mechanical system’s natural resonant frequency, causing a rapid and often destructive increase in vibration. You can avoid it by using a high-quality, stiff, and well-balanced blower wheel as a first defense and by programming the VFD’s “skip frequency” parameter to prevent the motor from operating continuously at that specific dangerous speed.

This is one of the most important technical considerations when implementing a VFD. Ignoring it can lead to catastrophic mechanical failure. Understanding the concept of resonance is key to preventing this problem.

Understanding Natural Frequency and System Resonance

Every physical object, from a guitar string to a bridge, has a natural frequency at which it prefers to vibrate. When you apply a force at this specific frequency, you get resonance—the vibrations amplify dramatically. A VFD, by its very nature, can operate the fan at any frequency within its range. If that operating frequency happens to match the natural frequency of the blower wheel, shaft, or supporting structure, you have a critical speed problem.

How VFDs Can Excite a System’s Critical Speed

In a constant-speed system, you are either lucky or unlucky—the fixed operating speed either matches the critical speed or it doesn’t. A VFD changes this. As it ramps the motor up and down, it will inevitably pass through the system’s critical speed. While passing through it quickly is usually fine, attempting to operate continuously at or near that speed will cause violent shaking, noise, and will quickly lead to bearing or structural failure.

Using the VFD’s Programming to “Skip” Dangerous Frequency Bands

Modern VFDs have a built-in safety feature to manage this. During system commissioning, a technician can identify the speeds at which vibration peaks. They can then program the VFD to “jump over” these specific frequency bands. For example, if the critical speed is found at 40 Hz, the VFD can be programmed to accelerate rapidly from 38 Hz to 42 Hz, never allowing the motor to dwell in that dangerous zone.

Important: A skip frequency is a programming fix, but the best solution is a better mechanical system. A well-designed, stiff, and precisely balanced blower wheel from a quality manufacturer will have a much higher critical speed, often outside the normal operating range entirely.

Frequently Asked Questions (FAQ)

Can I install a VFD on my existing blower system?

Often, yes. Most standard three-phase AC induction motors are compatible with VFDs. The key considerations are the condition of the motor’s insulation (older motors may need to be upgraded), the mechanical integrity of the blower wheel and bearings, and ensuring the system is properly commissioned to avoid issues like critical speed.

How much money can a VFD on a blower fan really save?

The savings can be substantial, often between 30% and 60% of the fan’s energy costs, depending on the system’s operating profile. According to the Fan Affinity Laws, even a modest 20% reduction in average speed can cut energy consumption by nearly 50%.

Does running a blower at a lower speed for a long time damage the motor?

It can, if not managed properly. Many motors rely on their own internal fan for cooling. At very low speeds, this fan is less effective. For applications requiring continuous operation below about 25% of the motor’s base speed, it may be necessary to use an inverter-duty motor or a separately powered cooling fan to prevent overheating.

What’s the difference between a VFD, a soft starter, and a simple motor starter?

A simple starter just turns the motor on and off. A soft starter provides a gentle ramp-up to full speed, reducing mechanical and electrical stress, but it cannot control the speed during operation. A VFD can do both: it provides a soft start and offers complete speed control throughout the entire operating cycle.

Are there any downsides or risks to using a VFD with a blower?

The primary risks are electrical and mechanical if not installed correctly. Electrical risks include potential motor damage from voltage spikes. Mechanical risks, as discussed, revolve around vibration and critical speed if the blower wheel is not well-balanced or if the VFD is not programmed correctly. These risks are easily mitigated with proper equipment selection and professional installation.

Why is my fan so loud or vibrating after installing a VFD?

This is a classic sign that you are operating at or near the system’s critical speed (resonant frequency). The VFD is exciting a natural vibration in the blower wheel or structure. The immediate solution is to identify and program a skip frequency. The long-term solution is to ensure you have a high-quality, dynamically balanced blower wheel.

Do I need a special “inverter-duty” rated motor to use a VFD?

For most variable-torque applications like fans and blowers, a standard NEMA design A or B motor is often sufficient. However, an inverter-duty motor is always a more robust choice. It has superior insulation to protect against voltage spikes from the VFD and is often designed for better cooling at lower speeds, providing a wider margin of safety and reliability.

Conclusion: The Blower Wheel is the Heart of Your Efficient System

The path to maximum efficiency is a complete system approach. It begins with understanding the incredible energy-saving potential unlocked by the Fan Affinity Laws. It continues with the intelligent application of a VFD to control motor speed. And it is successful only when you master the technical details, like choosing the right blower wheel design and avoiding critical speeds. When all these elements work in harmony, the results are dramatic.

However, it is crucial to remember that a sophisticated electronic controller cannot fix a poor mechanical foundation. The VFD is the brain, but the blower wheel is the heart of your system. All the potential savings and precise control of a VFD will be negated if the blower wheel is unbalanced, structurally weak, or aerodynamically inefficient. Vibration, noise, and premature bearing failure will erase your ROI and cause system downtime.

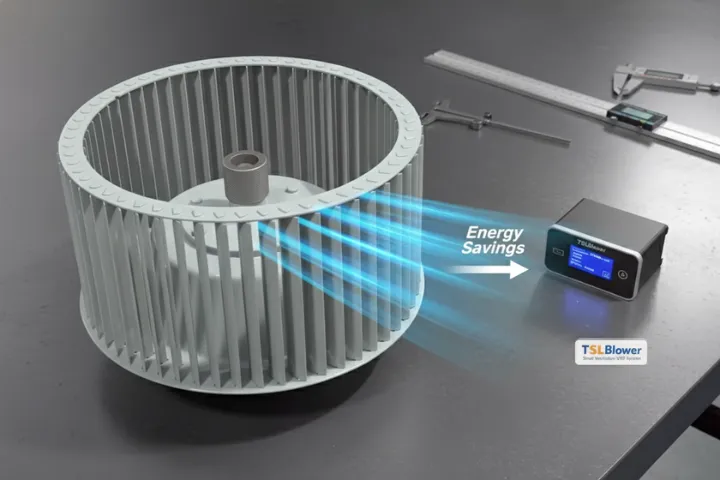

Build your high-efficiency system on a solid foundation. At TSLBlower, we specialize in engineering and manufacturing blower wheels that are built for the demands of modern VFD applications. Our impellers are dynamically balanced for smooth operation across the entire speed range and constructed to withstand the rigors of variable torque. Contact our engineering team today to discuss your VFD project and get a quote for a blower wheel that will ensure your system achieves maximum performance and reliability.