Custom Kitchen Oven Fan Impeller Manufacturer

Tslblower is your one-stop supplier for top-quality blower wheel solutions in the industrial and commercial markets. We’re a professional manufacturer that specialize in designing and manufacturing standard and custom blower impellers that fit your specific project demands.

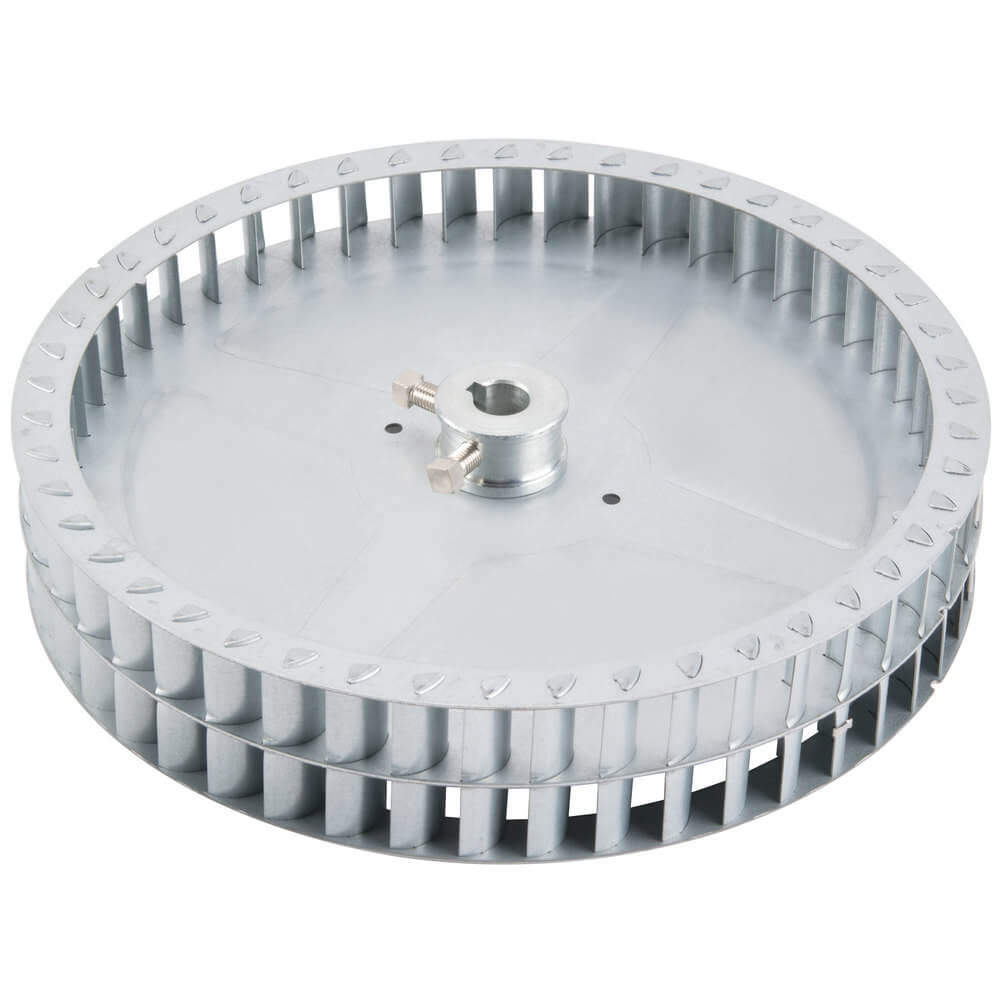

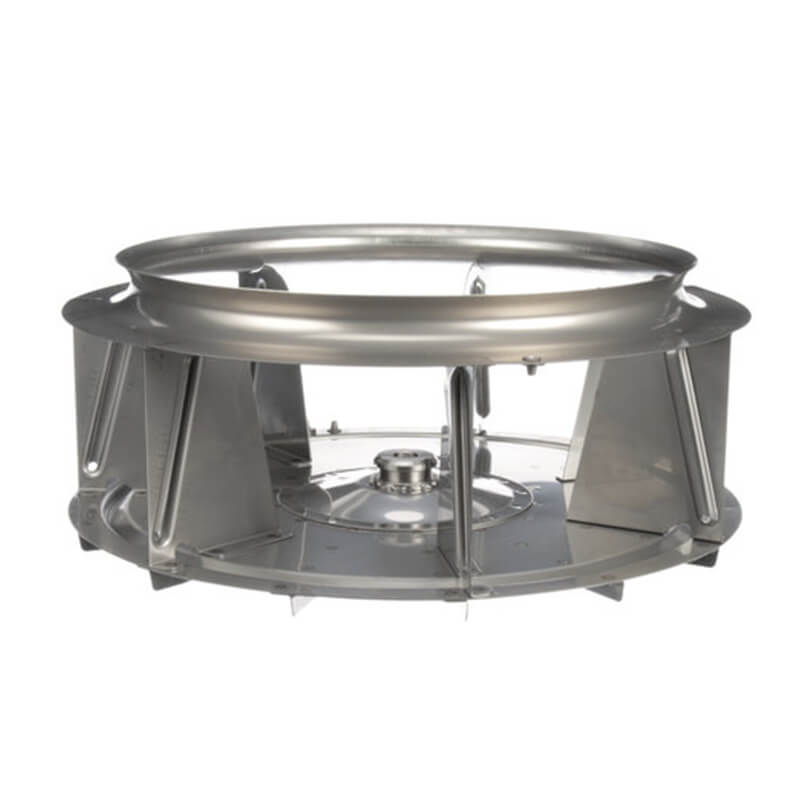

Our Feature Kitchen Oven Fan Impellers

The impeller of a kitchen oven is a crucial component that ensures even heating by forcing hot air circulation. There are three main types of impellers: axial flow, centrifugal, and vertical blade.

Advantages of Kitchen Oven Fan Impellers

High-efficiency Air Circulation

The impeller forces hot air to circulate within the oven, ensuring even heating of the food. This enhances cooking efficiency and guarantees the taste and quality of the food.

High Temperature Tolerance

Made from high-temperature resistant metal materials, the impeller can operate stably in high-temperature environments, ensuring the oven's long-term durability.

High-quality Materials

Most impellers are made of stainless steel, which not only withstands high temperatures but also prevents corrosion and oxidation, extending the service life.

Flexible Rotation Direction

The vertical blade impeller can rotate both clockwise and counterclockwise, ensuring even heating of the food and improving the overall cooking effect.

Wide Applications

Impellers are widely used in both commercial and domestic ovens. They are especially beneficial in baking, grilling, and drying processes, significantly improving cooking efficiency and results.

Improved Food Quality

By enabling high-efficiency air circulation, the impeller ensures food is heated evenly within the oven, avoiding local overheating or cooling. This guarantees the best taste and quality of the food.

Why Choose Us As Your Oven Fan Impeller Partner

Excellent Manufacturing Technology

Tslblower adopts advanced manufacturing technology and automated production processes to ensure the precision and quality of each impeller. This not only improves the performance of the impeller but also reduces production operation time, extending its service life

High-quality Material Selection

Tslblower uses stainless steel and other high-quality metal materials with strong high-temperature tolerance to manufacture impellers. This ensures that the impeller can operate stably and long-term in high-temperature environments. Additionally, these materials have anti-corrosion and anti-oxidation properties, further extending the product’s service life.

Strict Quality Control

Tslblower implements strict quality control measures during the production process. From the selection of raw materials to the inspection of finished products, every step is rigorously checked to ensure the high quality and reliability of the product.

Flexible Customized Service

Tslblower is a leading manufacturer for western kitchen equipment, providing customers with high-performance, high-durability, and high-reliability product solutions according to the special needs of customers to meet the specific application requirements of different types of ovens..

7 Steps To Get Your Custom Kitchen Oven Fan Impellers

01. Demand Analysis and Design

Our engineers will conduct detailed design and modeling to generate technical drawings and 3D models of the impeller by analyzing the customer’s needs and specific application.

02. Raw Material Selection

Select high-quality raw materials according to design requirements. Common materials include stainless steel and other metals known for high temperature tolerance, corrosion resistance, and oxidation resistance.

05. Balance Correction

After assembly, the impeller is placed on a balancing machine for balance correction to ensure smooth operation.

03. Cutting and Forming

Use laser cutting or stamping to cut the raw materials into the required parts for the impeller.

06. Quality Inspection

Implement strict quality inspections throughout the production process. The final product undergoes a series of performance tests and quality checks, including dimensional accuracy, balance, strength, and high-temperature resistance tests, ensuring that each impeller meets design requirements and quality standards.

04. Welding and Assembly

Assemble the impellers by joining the cut parts together. Depending on the design requirements, welding may be necessary. During this process, it is crucial to ensure welding quality and assembly accuracy to maintain the impeller’s stability.

07. Packaging and Delivery

The impellers that pass quality inspection are carefully packaged with protective measures to prevent damage during transportation. Finally, the impellers are shipped to the customer’s designated location.

Frequently Asked Questions

The oven impeller is one of the important parts inside the oven. It is mainly used to force hot air circulation to ensure that the food is heated evenly. This not only improves cooking efficiency, but also ensures the taste and quality of the food.

Impellers are mainly divided into three types: axial flow impellers, centrifugal impellers, and vertical blade impellers. Axial flow impellers are suitable for small ovens and pizza chain ovens, centrifugal impellers are suitable for large ovens, and vertical blade impellers are often used in hot air ovens and combination ovens.

Impellers are usually made of stainless steel or other high-quality metal materials with strong high-temperature tolerance. These materials can not only work stably in high-temperature environments, but also have anti-corrosion and anti-oxidation properties, which prolong the service life of the impeller.

While impellers are often made of stainless steel with strong high-temperature tolerance, it is still necessary to clean the impeller surface regularly to prevent dust and oil accumulation, thus maintaining its efficient operation.

After the impeller is assembled, it needs to be balanced on a balancing machine to ensure that it runs smoothly at high speed. This step is very important because an unbalanced impeller will cause the oven to vibrate, affecting the cooking effect and the life of the equipment.

Strict quality control measures are implemented during the production process, covering all links from raw material selection to finished product testing. The final product must pass a series of performance tests and quality inspections, such as dimensional accuracy, balance, strength, and high temperature resistance tests, to ensure that each impeller meets design requirements and quality standards.

The oven impeller can be disassembled, cleaned, and then reinstalled to maintain optimal performance.