Blower wheels are essential components in various industrial applications, from ventilation to HVAC systems. But with so many types available, how do you know which one is best for your needs? In this post, we will explore the different types of blower wheels, their features, and the benefits of each.

Blower wheels come in several different types, each designed for specific applications. From the open radial blade to the backward curved options, the design of the blower wheel impacts airflow, energy efficiency, and noise levels.

Understanding these various types can help you make an informed decision when choosing the right blower wheel for your business. Let’s dive deeper into the specific types and what makes each of them unique.

Table of Contents

Toggle9 Types of Blower Wheels and Centrifugal Impellers

There are 9 primary designs of blower wheels or centrifugal impellers commonly utilized in industrial blowers:

- Shrouded Radial Blades

- Open Radial Blades

- Open Paddle Wheels

- Backward Inclined Blades

- Backward Curved Blades

- Airfoil Blades

- Forward Curved Multi-vane (Squirrel Cage)

- Backward Curved Radial Blades

- Radial Tip Blades

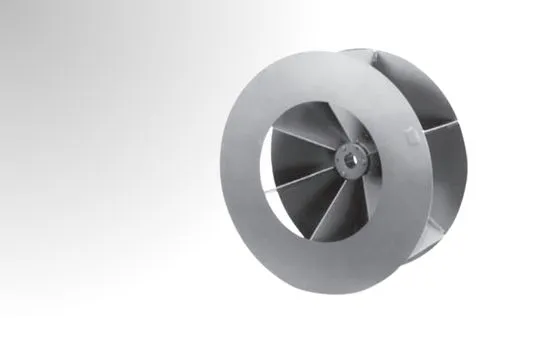

What Is Shrouded Radial Blade?

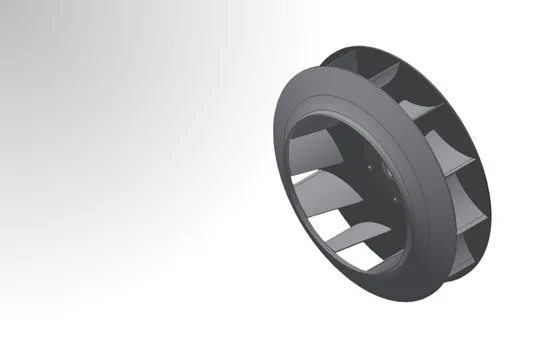

The Shrouded Radial Blade is one of the most common designs used in blower wheels. It offers a combination of efficiency and protection that makes it suitable for a wide range of applications.

The Shrouded Radial Blade has blades enclosed by a casing or shroud, which helps protect the blades and improve efficiency by directing airflow in a more controlled manner.

The shrouded design helps maintain a consistent airflow, which is important for systems that require steady performance, such as in HVAC systems or commercial ventilation. The protective casing not only improves efficiency by reducing drag but also extends the lifespan of the wheel by shielding it from debris and damage.

The primary benefit of the shrouded radial blade is its ability to provide higher static pressure while maintaining a low noise level. This makes it ideal for applications where both quiet operation and high airflow are needed. Its efficiency also allows for energy savings in the long run, which is crucial for businesses aiming to reduce operational costs.

What Is Open Radial Blade?

Open Radial Blade blower wheels are known for their simple design and high versatility. This type of wheel is frequently used in industries where airflow needs to be maximized without adding too much weight to the system.

The Open Radial Blade design features blades that extend outward from the hub without a casing or cover. This structure allows air to flow freely through the blades, maximizing airflow.

The open design of the radial blade makes it an excellent choice for applications requiring high volumes of air with less concern for noise levels or pressure. Common applications include fans for cooling systems or large ventilation setups. However, the open structure also makes the wheel more susceptible to damage from external factors, such as dust or debris.

While these wheels are generally less efficient than shrouded versions in terms of static pressure, their simplicity and cost-effectiveness make them suitable for less demanding tasks. They are often used in residential or light commercial applications where cost and airflow volume are the main considerations.

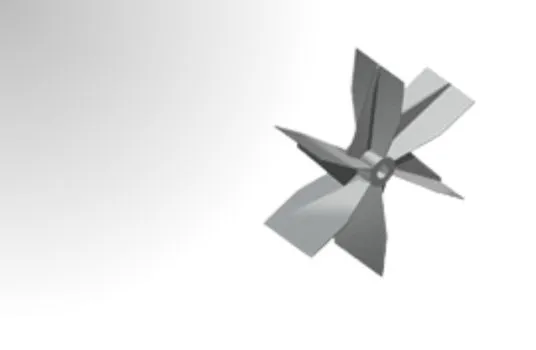

What Is Open Paddle Wheel?

The Open Paddle Wheel is another variant commonly used in different air-moving applications. Its paddle-like blades are designed to generate high airflow at lower speeds.

Open Paddle Wheels feature flat, paddle-shaped blades that push air with a high volume but lower pressure. This design is great for applications where airflow is more critical than static pressure.

The Open Paddle Wheel excels in applications requiring the movement of large amounts of air, such as in grain drying, cooling towers, or other large-scale air handling systems. The blades’ shape and design allow them to move air efficiently, but they are not ideal for applications needing high pressure.

This type of blower wheel is often used in environments where the airflow is more important than the speed or pressure of the air being moved. The relatively simple design also helps reduce manufacturing costs, making it an economical choice for large-scale industrial projects.

What Is Backward Inclined?

Backward Inclined blower wheels are known for their efficiency and ability to handle high-pressure systems. They are typically used in environments where air needs to be moved against resistance.

The Backward Inclined wheel has blades that are slanted away from the direction of airflow, which helps reduce turbulence and increases efficiency by minimizing drag.

Backward inclined wheels are designed to provide higher airflow at higher pressures, which makes them ideal for handling difficult environments like high-static pressure systems. This design minimizes the risk of cavitation and the associated drop in efficiency, making it an excellent choice for high-performance applications.

These blower wheels are often used in HVAC systems, air filtration units, and other industrial applications where maintaining high airflow and pressure is crucial. They are also preferred in systems where noise is a concern, as their design reduces vibration and noise during operation.

What Is Backward Curved?

The Backward Curved blower wheel features blades that are curved in the opposite direction of the airflow. This design is particularly effective at delivering high air pressure while maintaining energy efficiency.

Backward Curved wheels are designed to improve airflow efficiency by using a curved blade that pushes air backward. This structure reduces energy loss and enhances performance in systems requiring high static pressure.

The backward curved design allows the wheel to maintain performance in environments where air is under pressure or needs to be moved through restrictive ducts. Unlike the backward inclined design, which minimizes drag, the backward curved wheel is better for scenarios requiring consistent high pressure over long periods.

This design is often used in industrial blowers, air-handling units, and other equipment where constant, high-pressure airflow is needed. The benefits include reduced power consumption and improved efficiency, making it a great choice for energy-conscious businesses.

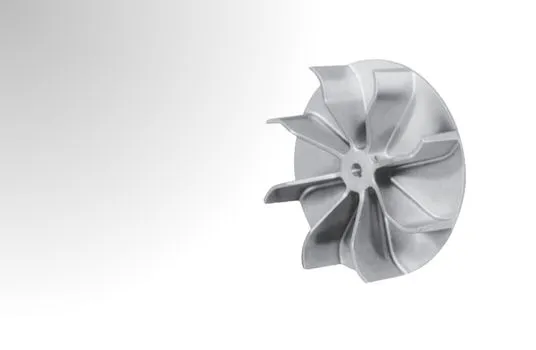

What Is Airfoil Blade?

Airfoil Blade blower wheels are designed for ultimate efficiency. Their aerodynamic shape allows for smooth airflow and minimized resistance, making them ideal for systems that prioritize energy savings.

Airfoil Blades feature a streamlined design that reduces drag and increases airflow efficiency. They are typically used in high-performance systems where energy efficiency is a top priority.

The airfoil shape of the blades allows air to flow smoothly over them, resulting in a significant reduction in energy loss. This design is particularly beneficial for commercial or industrial applications that need to operate at optimal efficiency while minimizing energy consumption.

These blower wheels are often used in HVAC systems, ventilation, and refrigeration units. Although they tend to be more expensive due to the advanced design, the energy savings over time often make them a cost-effective choice for large-scale operations.

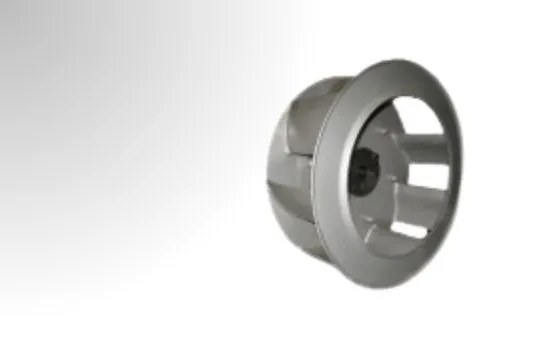

What Is Forward Curved Multi-vane (Squirrel Cage)?

The Forward Curved Multi-vane, also known as the squirrel cage, is one of the most widely recognized blower wheel designs. It is favored for its ability to generate high air volume in compact spaces.

This design features a series of forward-curved blades that are arranged like the spokes of a wheel. It is commonly used for applications requiring a compact blower system.

The Forward Curved Multi-vane blower wheel is ideal for systems with tight spaces where maximizing air volume is crucial. Its design ensures that air is moved efficiently even in compact units like fans and air conditioning systems.

The primary advantage of this design is its ability to produce high airflow at low pressure, which makes it a good choice for air conditioning units, furnaces, and other systems where air distribution over a wide area is required. However, its low-pressure capacity makes it unsuitable for high-resistance environments.

What Is Backward Curved Radial?

Backward Curved Radial blower wheels are a unique blend of backward curved blades with a radial arrangement. They combine high-pressure capabilities with lower noise levels, making them ideal for both industrial and commercial applications.

This type of wheel features backward-curved blades arranged radially, improving performance in systems that require high airflow with reduced noise.

The Backward Curved Radial blower wheel is designed for high-performance systems where both high pressure and low noise levels are necessary. This combination makes it suitable for sensitive environments such as laboratory air systems or data centers.

In industrial settings, the backward-curved radial design can handle tough workloads and challenging airflow situations, offering excellent performance with minimal maintenance needs.

What Is Radial Tip?

Radial Tip blower wheels feature blades that end in a radial tip, which allows for increased efficiency and pressure at the wheel’s outer edge.

Radial Tip wheels focus on moving air efficiently by optimizing the blade’s design to enhance airflow while minimizing drag.

The Radial Tip design ensures that air is efficiently pushed toward the outer edges of the wheel, improving both airflow and pressure. This design allows for increased performance in high-pressure applications while maintaining energy efficiency.

Radial Tip blower wheels are commonly used in situations where consistent airflow at high pressures is required. They are ideal for ventilation systems and other industrial applications that need both high volume and high-pressure output. These wheels offer significant energy savings over time by reducing the amount of work the motor needs to do to push air through restrictive systems.

Conclusion

Choosing the right types of blower wheels depends on your specific needs. Whether it’s high airflow, high pressure, energy efficiency, or low noise. From Shrouded Radial Blades to Radial Tip designs, each type offers unique advantages for various industrial and commercial applications. Understanding these options will help you make a more informed decision, ensuring optimal performance and efficiency in your air-moving systems.