In any large-scale HVAC system or industrial process, the monthly energy bill often reads like a mystery novel filled with cryptic charges. A significant portion of that cost, often hidden in plain sight, comes from the fans and blowers running 24/7. Many facilities are unknowingly wasting thousands of dollars annually, not because their equipment is old, but because it’s fundamentally inefficient. The culprit is often a blower wheel operating far from its peak performance, consuming excessive power to do its job. This isn’t just about being “green”; it’s about pure financial and engineering sense. Understanding and calculating blower wheel efficiency is the key to unlocking massive energy savings, reducing operational noise, and extending the life of your entire air-handling system.

To calculate blower wheel efficiency, you must determine the ratio of the fluid power output to the mechanical power input. This is done using a formula that incorporates the airflow volume (Q), the total pressure generated by the fan (P), and the brake horsepower (BHP) consumed by the fan shaft. It is the single most important metric for quantifying a fan’s ability to convert input power into useful work.

But let’s be honest, formulas can be intimidating, and the term “efficiency” is thrown around so often it can lose its meaning. This guide is designed to change that. We’re going to demystify the process, breaking down the calculations into clear, manageable steps. Think of it as learning the language of your fan. By the end of this article, you won’t just see a blower wheel as a spinning piece of metal; you’ll see a dynamic system of airflow, pressure, and power. You’ll be able to look at a fan curve and pinpoint its sweet spot, calculate its real-world efficiency, and make informed decisions that will have a direct, positive impact on your system’s performance and your company’s bottom line.

Table of Contents

ToggleWhat is Blower Wheel Efficiency and Why is it the Most Critical Metric for Fan Performance?

Blower wheel efficiency is a percentage that measures how effectively a fan converts the mechanical energy it receives from a motor (input) into useful work in the form of moving air (output). It is the most critical performance metric because it directly quantifies wasted energy. An inefficient fan consumes excessive power to perform its task, leading to higher electricity bills, increased heat generation, more noise, and greater wear on components.

The Simple Truth: Output vs. Input

At its core, efficiency is a simple concept that applies to any machine. It answers the question: “How much of the energy I put in am I getting back as useful work?” For a blower wheel, the equation looks like this:

Efficiency (η) = Power Output (Air Power) / Power Input (Shaft Power)

The “Power Input” is the energy delivered to the fan’s shaft by the motor (Brake Horsepower). The “Power Output” is the work done on the air, which is a combination of the volume of air moved and the pressure it’s moved against. The difference between these two numbers is pure waste, lost primarily as heat and noise due to turbulence and friction within the fan.

The Tangible Benefits of High Efficiency

Focusing on efficiency isn’t just an academic exercise; it has direct, real-world benefits that impact your budget and operations.

- Lower Energy Costs: This is the most obvious benefit. An 80% efficient fan requires significantly less electricity to do the same job as a 60% efficient fan. In continuous-duty applications, these savings accumulate rapidly, often paying back the initial investment in a higher-quality fan in a short period.

- Reduced Noise Levels: Inefficiency and noise are two sides of the same coin. The primary cause of both is turbulence. A highly efficient aerodynamic design moves air smoothly, minimizing the chaotic air patterns that generate noise. A quieter fan often indicates a more efficient fan.

- Longer Component Life: An inefficient fan is a fan working harder than it needs to. This extra strain translates to higher operating temperatures and greater vibrational loads on the motor, bearings, and belts. A more efficient fan runs cooler and smoother, extending the life of the entire drive assembly and reducing maintenance costs.

What are the Key Variables Required for an Accurate Efficiency Calculation?

To accurately calculate blower wheel efficiency, you need three key variables from a fan’s performance data at a specific operating point: Airflow Volume (Q), which is the amount of air being moved; Pressure (P), which is the force generated to move the air; and Power Input (BHP), which is the mechanical power consumed by the fan’s shaft to perform the work.

Gathering Your Data: The Essential Inputs

Before you can plug numbers into a formula, you need to understand what those numbers represent. These three variables are the fundamental building blocks of any fan performance analysis.

A. Airflow Volume (Q)

This is the “how much” of the equation. It quantifies the volume of air that the fan moves over a period of time. It’s typically measured in:

- CFM (Cubic Feet per Minute): The standard unit in the United States and Imperial systems.

- m³/s (Cubic Meters per Second) or m³/hr (Cubic Meters per Hour): The standard units in the SI or metric system.

B. Pressure (P): The Three Types of Pressure

This is the “how hard” part of the equation. Fan pressure is the force exerted by the air, and it’s crucial to understand its three distinct components:

| Pressure Type | Description | Analogy |

|---|---|---|

| Static Pressure (SP) | The pressure that pushes against the walls of the duct. It’s the potential energy required to overcome system resistance (filters, bends, etc.). | The pressure inside a balloon pushing outwards. |

| Velocity Pressure (VP) | The pressure created by the air’s own movement and speed. It’s the kinetic energy of the air. | The force of the wind hitting your face. |

| Total Pressure (TP) | The sum of Static Pressure and Velocity Pressure. It represents the total energy imparted to the air by the fan. | The combined force of the balloon’s internal pressure and the wind it creates when released. |

The fundamental relationship is simple: Total Pressure (TP) = Static Pressure (SP) + Velocity Pressure (VP). Understanding this is key to choosing the right efficiency calculation.

C. Power Input (BHP)

This is the “how much energy” input. Brake Horsepower (BHP) is the actual power delivered to the fan shaft from the motor. It’s important to note that this is *not* the same as the motor’s nameplate horsepower. The BHP is the power the fan is actually consuming at a specific point on its performance curve. It does not include energy losses from the motor or the drive system (belts, etc.).

How Do You Calculate Static Efficiency vs. Total Efficiency?

You calculate efficiency using a formula that divides the air power by the shaft power. The choice between calculating Static Efficiency or Total Efficiency depends on which pressure value you use. Static Efficiency uses Static Pressure (SP) and measures the fan’s ability to overcome system resistance. Total Efficiency uses Total Pressure (TP) and measures the fan’s overall effectiveness at imparting energy to the air.

The Formulas Unpacked

Here are the two standard formulas used in the industry for calculating fan efficiency using Imperial units. These formulas include a conversion constant (6356) to handle the mix of units (CFM, inches of water, and horsepower).

Static Efficiency (η_s)

(Q × SP) / (6356 × BHP)

Total Efficiency (η_t)

(Q × TP) / (6356 × BHP)

Where:

- η (“eta”) is the efficiency, expressed as a decimal (e.g., 0.75 for 75%).

- Q is the Airflow Volume in CFM.

- SP is the Static Pressure in inches of water gauge (in. wg).

- TP is the Total Pressure in inches of water gauge (in. wg).

- BHP is the Brake Horsepower.

- 6356 is the constant to convert the units into a consistent horsepower-to-horsepower ratio.

Which Efficiency Should You Use?

The choice between static and total efficiency is a common point of confusion, but the application usually makes the decision clear. Since Total Pressure is always greater than or equal to Static Pressure, the calculated Total Efficiency will always be higher than or equal to the Static Efficiency.

| Efficiency Type | When to Use It | What It Tells You |

|---|---|---|

| Static Efficiency | This is the most commonly used metric for ducted systems (e.g., HVAC, industrial exhaust). | It measures how efficiently the fan uses energy to overcome the resistance of the ductwork, filters, and other components. The velocity pressure is often considered “lost” at the end of the duct, so static is what matters. |

| Total Efficiency | Used for applications where the velocity of the exiting air is also doing useful work (e.g., jet fans, un-ducted plenum fans, material conveying). | It represents the fan’s total energy transfer to the air. It’s a more complete measure of the fan’s aerodynamic perfection but can be misleading for ducted systems where exit velocity is not useful. |

Industry Standard Warning: Always be sure which efficiency is being quoted. Some manufacturers may advertise the higher Total Efficiency number to make their product seem more competitive. For most ducted applications, Static Efficiency is the more honest and practical measure of real-world performance.

How Do You Read a Fan Curve to Find the Best Efficiency Point (BEP)?

You find the Best Efficiency Point (BEP) by locating the peak of the efficiency curve on a fan’s performance graph. This point on the “bell-shaped” efficiency line corresponds to a specific airflow (CFM) and pressure (SP) on the main fan curve. Operating the fan at this precise point ensures it is converting the maximum amount of input power into useful work, guaranteeing the lowest energy consumption for that performance.

Decoding the Map to Peak Performance

A fan performance curve is a map that details a fan’s capabilities. Instead of roads and cities, it plots airflow, pressure, power, and efficiency. Learning to read this map is the most important skill for selecting an energy-efficient fan.

Visualizing a Typical Fan Curve

(Conceptual Representation)

- X-Axis (Horizontal): Airflow Volume (CFM) – Increases from left to right.

- Left Y-Axis (Vertical): Static Pressure (SP) – Decreases as airflow increases. This is the main Fan Curve.

- Right Y-Axis (Vertical): Brake Horsepower (BHP) – Shows power consumption.

- The Bell Curve (η): Superimposed on the graph is the Efficiency Curve. It starts at zero, rises to a peak, and falls back to zero.

The Best Efficiency Point (BEP) is the absolute peak of that bell-shaped efficiency curve. It represents the single point where the fan’s aerodynamic design is in perfect harmony with its operating conditions. At the BEP, the fan is at its “happiest”—it’s producing a good combination of pressure and flow with the least amount of wasted energy.

Why Operating Near the BEP is Non-Negotiable

Selecting a fan to operate at or very close to its BEP is the primary goal of any good system designer. Drifting too far away from this point has significant negative consequences:

- Wasted Energy: Even a small shift away from the BEP can cause a dramatic drop in efficiency, leading to higher energy bills.

- Increased Noise and Vibration: As you move away from the BEP, the airflow inside the fan becomes more turbulent and unstable. This instability is the direct cause of increased noise and vibration, which leads to premature wear on bearings and motors.

- Unreliable Performance: Some fan types, particularly forward-curved models, can enter an unstable “stall” region if operated too far to the left of the BEP, causing performance to fluctuate wildly.

Which Design and System Factors Have the Biggest Impact on Real-World Efficiency?

Beyond the calculation itself, the two factors with the biggest impact on real-world efficiency are the inherent aerodynamic design of the wheel (e.g., backward-curved wheels are more efficient than forward-curved) and the presence of “System Effects.” System Effects are performance losses caused by poor ductwork design near the fan’s inlet or outlet, which can slash the efficiency of even the best fan.

It Starts with the Wheel’s DNA

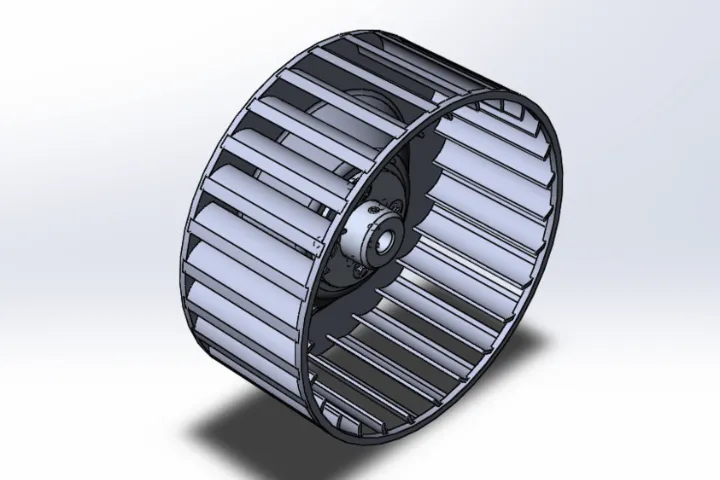

The maximum possible efficiency is baked into the physical design of the blower wheel. Different designs have different efficiency ceilings.

- Backward-Curved & Airfoil Wheels: These are the champions of efficiency. Their blades are shaped to slice cleanly through the air, minimizing turbulence and efficiently converting rotational energy into pressure. They can achieve static efficiencies of 80% or higher.

- Forward-Curved Wheels: These wheels act more like “slingers,” using many small blades to scoop and throw the air. While they are excellent for moving high volumes of air at low speeds, their aerodynamic process is inherently more turbulent and less efficient, with typical peak efficiencies in the 60-70% range.

The Silent Killer: System Effects

This is the most misunderstood concept in fan performance. A fan’s published performance curve is based on tests performed under ideal laboratory conditions with long, straight, unobstructed ducts. Your real-world installation is almost never ideal. Any poorly designed ductwork immediately connected to the fan’s inlet or outlet will disrupt the airflow, creating turbulence and preventing the fan from performing as advertised. This performance degradation is called the System Effect.

A Critical Point: System Effects don’t make the fan less efficient; they increase the amount of work the fan has to do. A sharp bend at the fan inlet forces the fan to work harder to pull in the same amount of air, effectively shifting your system’s resistance curve up and forcing the fan to operate at a less efficient point on its curve.

Common causes of system effects include:

- Sharp Bends or Elbows: Placing an elbow directly on the fan’s inlet or outlet.

- Abrupt Transitions: Suddenly changing the duct size or shape right at the fan connection.

- Inlet Obstructions: Guards, dampers, or other components that block or pre-swirl the air entering the fan.

Fan Efficiency vs. “Wire-to-Air” Efficiency

It’s also important to remember that the fan efficiency we’ve been calculating (η_s or η_t) is only one piece of the puzzle. The total system efficiency, often called “wire-to-air” efficiency, also accounts for losses in the motor and the drive system.

Wire-to-Air Efficiency = Fan Efficiency × Motor Efficiency × Drive Efficiency

A highly efficient fan paired with an old, inefficient motor and loose belts will still result in a wasteful system. Optimizing for true energy savings means looking at all three components.

Are There Common Mistakes to Avoid When Calculating and Specifying Fan Efficiency?

Yes, several common mistakes can lead to poor fan selection. The most frequent errors include ignoring system effects, which leads to undersized fans; confusing static and total efficiency, which can create false comparisons; selecting a fan far from its Best Efficiency Point (BEP) to save on initial cost; and relying on uncertified or outdated performance data from a manufacturer.

Four Pitfalls That Can Derail Your Design

Why Does Accurate Efficiency Calculation Lead to Better System Design and Lower Lifetime Costs?

Accurate efficiency calculation is the foundation of value engineering. It transforms fan selection from a simple component purchase into a strategic decision about long-term operational costs. By prioritizing efficiency, you design a system that not only meets its performance targets but does so with the minimum possible energy consumption, leading directly to a lower total cost of ownership, easier compliance with energy codes, and a more reliable, sustainable operation.

Connecting the Dots from Calculation to Cost Savings

The initial purchase price of a fan is often only a small fraction of its total lifetime cost. The real expense is the electricity it consumes over years of operation. An accurate efficiency calculation allows you to quantify this future expense and make a smarter investment.

Example: Consider two fans for a 24/7 application. Fan A costs $1,500 and is 65% efficient. Fan B costs $2,000 and is 80% efficient. While Fan A is cheaper upfront, its higher energy consumption could cost an extra $1,000 per year in electricity. Over a 10-year lifespan, choosing the more efficient Fan B results in a net savings of $9,500. Accurate calculation allows you to see this long-term value.

This focus on efficiency leads to smarter system design. It forces you to consider factors like system effects, leading to better ductwork layouts. And it encourages the selection of premium efficiency motors and well-maintained drives. It shifts the entire design philosophy from “does it work?” to “how well does it work?”

Stop Wasting Energy. Start Engineering Efficiency.

Understanding and applying these principles is the key to designing air-handling systems that are powerful, quiet, and economical. But you don’t have to do it alone. Partnering with an expert manufacturer can give you the confidence that your calculations translate into real-world performance.

For over 20 years, TSLBlower has been dedicated to the science of air movement. We provide not just high-quality blower wheels, but the engineering support to help you select the most efficient solution for your application.

- ✓ Expert Consultation: Our engineers can help you analyze your system and select a wheel that operates at its BEP.

- ✓ Certified Performance Data: We provide reliable, tested performance curves so you can calculate and specify with confidence.

- ✓ Custom Optimized Solutions: From high-efficiency backward-curved wheels to compact forward-curved designs, we have the right product for your needs, with zero MOQ.

Make your next project your most efficient one yet.