Choosing the right material for a blower wheel is more than a simple selection—it’s a critical engineering decision that directly impacts performance, operational lifespan, safety, and your total budget. The wrong choice can lead to premature failure from corrosion, excessive energy consumption from unnecessary weight, or even non-compliance with industry standards.

The best material depends entirely on the application: Galvanized Steel is the cost-effective workhorse for general-purpose HVAC. Aluminum is the ideal choice for applications requiring low weight and natural corrosion resistance. Stainless Steel is the mandatory, premium solution for harsh, high-temperature, or hygienic environments like food processing and chemical labs.

Feeling uncertain about which path to take? You’re not alone. This guide will break down the science behind each of these core materials. We will explore their unique strengths, their critical weaknesses, and the specific applications where they excel, empowering you to select the perfect material for your next project with confidence.

Table of Contents

ToggleWhat Are the Key Factors in Selecting a Blower Wheel Material?

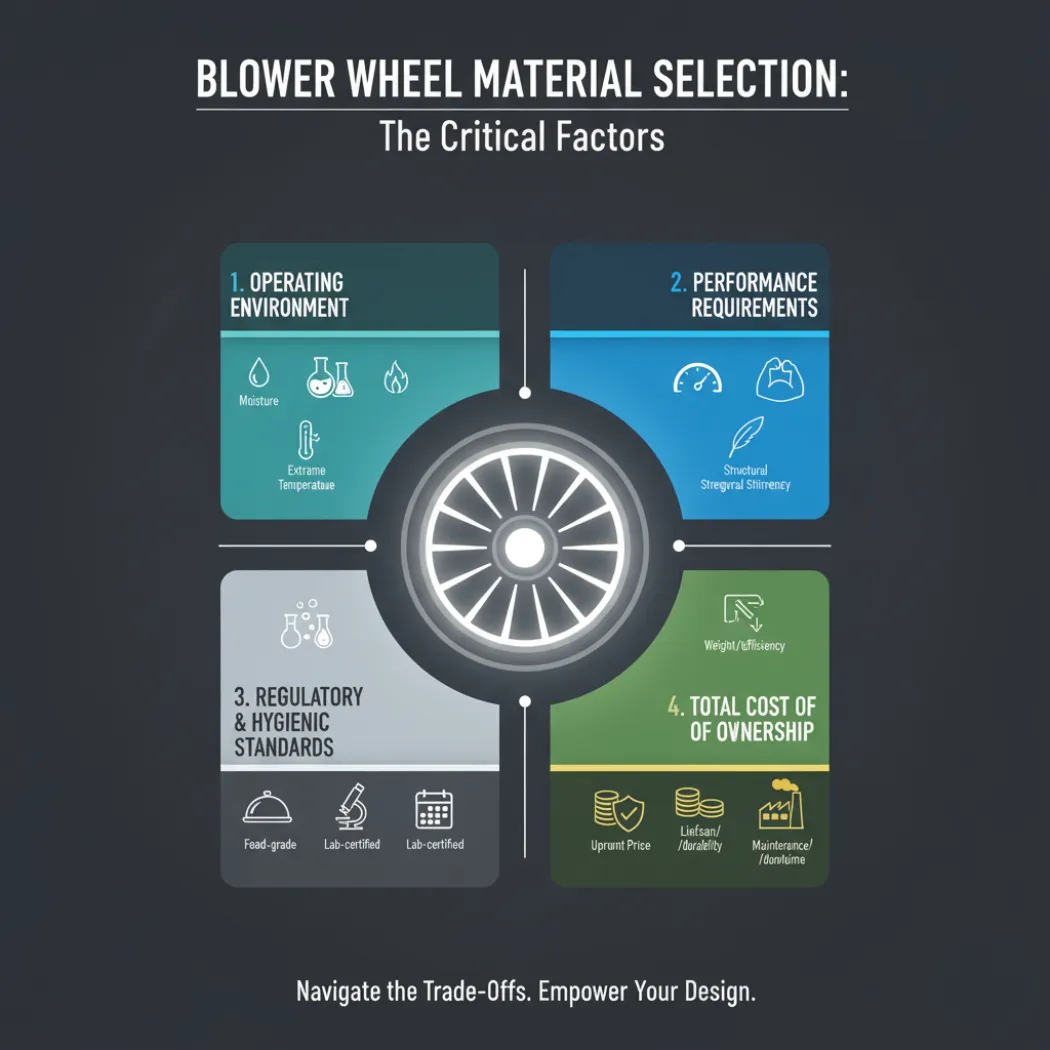

To select the right blower wheel material, you must evaluate four key factors: the operating environment (temperature, moisture, chemicals), performance requirements (weight, speed, structural strength), regulatory standards (food-grade, lab-certified), and the total cost of ownership, which balances upfront price against the component’s expected lifespan and maintenance needs.

Before we compare the metals head-to-head, it’s essential to understand the criteria we’ll be judging them by. Every engineering decision is a series of trade-offs, and material selection is no different. By defining your project’s priorities across these four areas, the right choice will become much clearer.

Operating Environment: Is Temperature, Moisture, or Corrosion Your Main Concern?

The single most important factor is the environment where the blower wheel will live. A wheel in a residential furnace faces a very different reality than one in a commercial convection oven or a marine ventilation system. Ask yourself: Will the air be humid or contain salt? Will the wheel be exposed to acidic fumes or caustic cleaning agents? What is the maximum continuous operating temperature it must endure? The answers to these questions will immediately begin to disqualify certain materials.

Performance Requirements: How Do Weight, Speed, and Structural Integrity Matter?

Performance is all about physics. A lighter wheel, like one made of aluminum, requires less energy (torque) to start and stop, which can be a significant advantage in applications with variable speeds. However, will the material be strong enough to handle the rotational stress of high RPMs without deforming? The material’s strength-to-weight ratio and its fatigue resistance are critical performance metrics that determine the wheel’s durability and efficiency.

Regulatory & Hygienic Standards: Are You Designing for Food-Grade or Lab Environments?

In many industries, material choice is not a suggestion; it’s a requirement. The food processing, pharmaceutical, and medical industries demand materials that are non-porous, easy to sanitize, and highly resistant to corrosion from cleaning chemicals. This is where materials like 304 or 316 stainless steel become mandatory to meet standards set by organizations like the NSF (National Sanitation Foundation).

Total Cost of Ownership: Looking Beyond the Upfront Material Price

It’s easy to look at the per-pound cost of a metal and make a quick decision. However, the true cost includes much more. A cheaper material that fails prematurely and causes system downtime is far more expensive in the long run. The total cost of ownership considers the initial purchase price plus the expected lifespan, potential maintenance, and the cost of failure. A premium material like stainless steel might have a higher upfront cost but could save you thousands in replacement parts and lost productivity.

How Does Galvanized Steel Perform as a Blower Wheel Material?

Galvanized steel performs as a cost-effective and structurally strong material for a wide range of general-purpose blower wheels, especially in standard HVAC applications. Its strength provides durability, while a zinc coating offers good protection against moisture and mild corrosion. However, its performance is limited in high-temperature, acidic, or chemically aggressive environments.

Galvanized steel is the most common material you’ll encounter for blower wheels, and for good reason. It represents a fantastic balance of strength, manufacturability, and cost. It starts as a standard carbon steel sheet, which is then coated in a layer of zinc. This zinc coating acts as a protective barrier, preventing the steel underneath from rusting.

The Primary Advantage: Unpacking the Cost-Effectiveness

Carbon steel is one of the most affordable and abundant metals in manufacturing. The galvanization process adds a minor cost but delivers a major benefit in corrosion protection. This combination makes galvanized steel the go-to choice for high-volume production and applications where budgets are a primary constraint, such as in residential furnaces, air handlers, and general ventilation systems.

Understanding Zinc Coating: What Level of Corrosion Resistance Does it Really Offer?

Think of the zinc coating as a sacrificial shield. When exposed to moisture, the zinc corrodes first, protecting the steel beneath it. This is known as “galvanic protection.”

This protection is highly effective against normal atmospheric humidity and condensation. It’s why galvanized steel wheels can last for decades inside a typical furnace. However, this shield has its limits. It is not designed to stand up to constant salt spray, acidic chemicals, or other highly corrosive agents, which will strip the zinc coating away and expose the vulnerable steel.

Key Limitations: Performance in High-Temperature and Chemical Environments

The zinc coating is the first point of failure in extreme conditions. Most galvanization methods are not rated for continuous service above 392°F (200°C), as the zinc layer can begin to peel or flake. Furthermore, the zinc is susceptible to attack from both strong acids and strong bases. This makes galvanized steel unsuitable for applications like chemical fume hoods or industrial ovens with corrosive vapors.

Common Applications: Where Galvanized Steel Shines

- Residential & Commercial HVAC Systems

- Air Handlers and Fan Coil Units

- General Purpose Ventilation and Exhaust Fans

- Dryer Blower Wheels

Why is Aluminum a Popular Choice for Specialized Blower Wheels?

Aluminum is a popular choice for blower wheels in applications where its low weight and excellent natural corrosion resistance are critical advantages. Its light weight reduces motor strain and energy consumption, especially in variable-speed systems. However, it offers lower structural strength and heat tolerance compared to steel, making it unsuitable for high-stress or high-temperature environments.

When you need to move air efficiently without adding much weight, aluminum is often the answer. It has about one-third the density of steel, a difference you can feel immediately. This lightness translates directly into performance benefits, and its unique surface chemistry gives it a built-in defense against rust.

The Lightweight Advantage: Impact on Motor Strain, Energy Use, and Portability

A lighter blower wheel requires less energy to spin up to speed and slow down. In systems that frequently cycle on and off or change speeds (like those with VFDs), this can lead to measurable energy savings over time. It also reduces the startup load on the motor bearings, potentially extending motor life. This makes it ideal for portable ventilation units, electronics cooling, and other applications where weight is a primary design concern.

Is it Naturally Corrosion-Proof? A Look at Aluminum’s Protective Oxide Layer

Unlike steel, which rusts and flakes away, aluminum reacts with oxygen in the air to form a very thin, hard, and transparent layer of aluminum oxide on its surface. This layer is passive and non-reactive, acting as a natural barrier that instantly stops further corrosion. It’s why aluminum ladders can be left in the rain without rusting. This property makes it excellent for applications with high humidity or exposure to the elements, such as marine ventilation.

Key Considerations: Structural Strength, Heat Tolerance, and Weldability

Aluminum’s biggest trade-off is its strength. It is not as strong or as hard as steel, which can make it susceptible to damage from debris or flexing at very high speeds. It also has a much lower melting point, generally making it unsuitable for applications that exceed 300°F (150°C). Finally, welding aluminum requires specialized equipment and techniques compared to steel, which can affect manufacturing complexity and cost.

Common Applications: Where Aluminum Excels

- Marine and Coastal Ventilation Systems

- High-Efficiency HVAC Systems

- Electronics and Server Rack Cooling

- Portable Fans and Blowers

When is Stainless Steel the Only Viable Option?

Stainless steel is the only viable option for blower wheels when the application involves extreme temperatures, aggressive corrosive agents, or strict hygienic standards. Its chromium content creates a self-repairing passive layer that resists heat, acids, and sanitizers, making it mandatory for food processing, pharmaceutical labs, and chemical processing plants despite its higher cost and weight.

When failure is not an option and the environment is trying its best to destroy the component, stainless steel is the undisputed champion. It is an alloy of steel, chromium, and often nickel. The chromium is the magic ingredient; it creates that same type of passive, corrosion-proof oxide layer as aluminum, but it’s far more durable and heat-resistant.

Unmatched Performance in Extreme Heat and Corrosive Environments

Different grades of stainless steel offer different properties, but most can easily handle continuous temperatures of 800°F (425°C) or much higher. The passive layer is also resistant to a wide range of acids, alkalis, and chlorides that would destroy galvanized steel and aluminum. This makes it the default choice for industrial ovens, chemical fume hoods, pollution control scrubbers, and other punishing environments.

Why It’s the Standard for Food-Grade, Pharmaceutical, and Laboratory Applications

Beyond its durability, stainless steel is chemically inert and non-porous. This means it won’t leach any substances into the products it comes near (like food), and its smooth surface is easy to clean and sanitize, leaving no place for bacteria to hide. This is why nearly every piece of equipment in a commercial kitchen, hospital, or lab is made from stainless steel.

The Trade-Offs: Analyzing the Higher Cost and Increased Weight

The performance of stainless steel comes at a price. The raw materials, particularly nickel, are expensive, making it the costliest option of the three. It is also dense and heavy, similar to regular steel, meaning it requires more energy to run than an equivalent aluminum wheel. The decision to use stainless steel is almost always driven by necessity rather than preference.

Common Applications: Where Stainless Steel is Essential

- Commercial Convection Ovens and Food Dehydrators

- Pharmaceutical and Chemical Fume Hoods

- Autoclaves and Sterilization Equipment

- Pollution Control and Exhaust Systems

Which Material is Right? A Side-by-Side Comparison

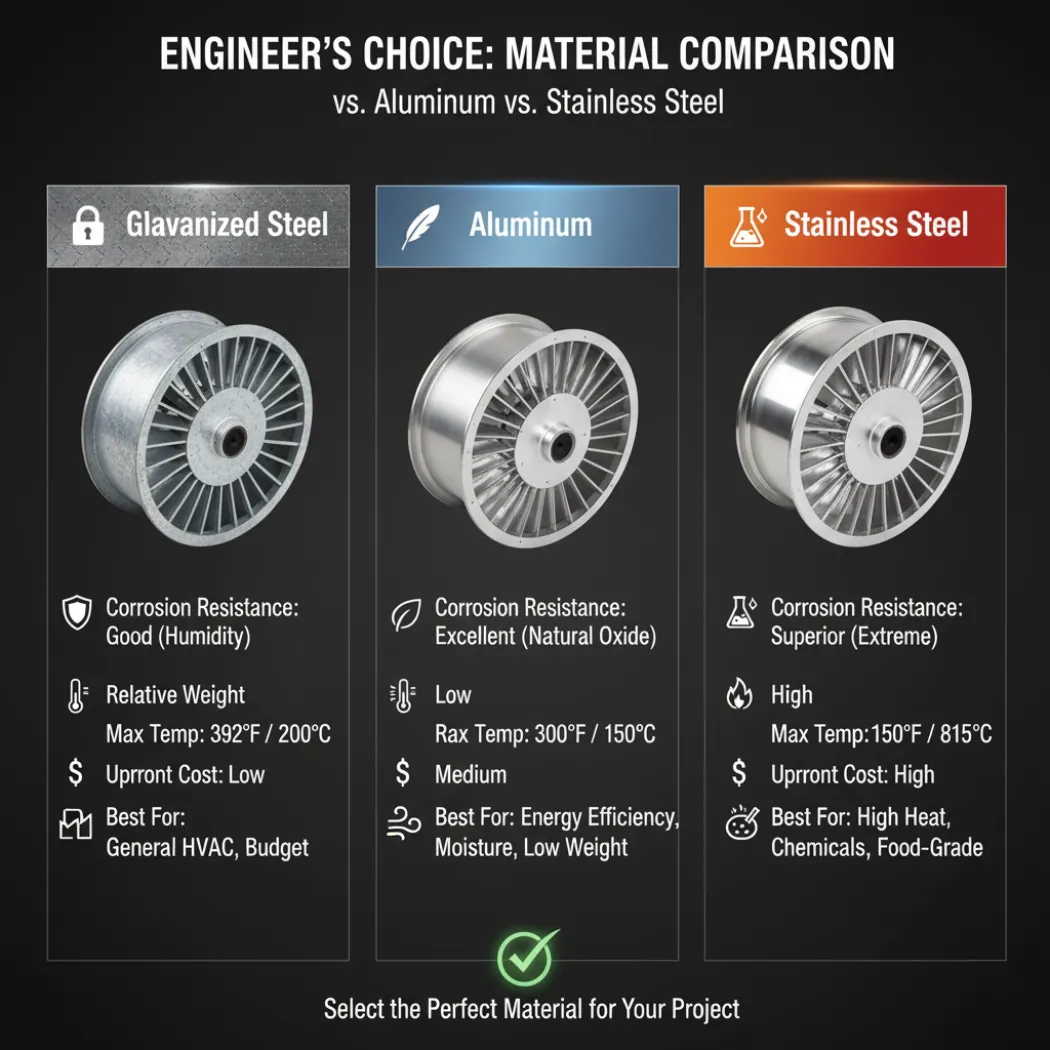

The right material is a trade-off between performance and cost for your specific environment. Galvanized steel is the best all-around value for standard applications. Aluminum excels where weight and moisture are key concerns. Stainless steel is the necessary choice for extreme heat, chemical exposure, or hygienic requirements.

To help you visualize the trade-offs, we’ve compiled all the key characteristics into a single comparison chart.

A Detailed Head-to-Head Material Breakdown

| Property / Factor | Galvanized Steel | Aluminum | Stainless Steel (304 Grade) |

|---|---|---|---|

| Corrosion Resistance | Good (in normal humidity) | Excellent | Superior |

| Relative Weight | High | Low | High |

| Max Continuous Temp. | ~392°F (200°C) | ~300°F (150°C) | ~1500°F (815°C) |

| Relative Upfront Cost | Low | Medium | High |

| Structural Strength | Excellent | Good | Excellent |

| Best For | General HVAC, budget-conscious projects | Energy efficiency, moisture, low weight needs | High heat, chemicals, food-grade |

Beyond the Base Material: Are Special Coatings an Alternative?

In some cases, a specialized coating (like epoxy or Heresite®) can be applied to a galvanized steel wheel to enhance its chemical resistance. While this can be a cost-effective alternative to stainless steel for some applications, it’s important to understand the coating’s limitations regarding temperature and abrasion resistance.

Frequently Asked Questions (FAQ)

What is the maximum operating temperature for each blower wheel material?

Generally, galvanized steel is limited to around 392°F (200°C) before the zinc coating can be compromised. Aluminum’s strength decreases significantly above 300°F (150°C). Common stainless steel grades like 304 can handle continuous service up to 1500°F (815°C) and even higher intermittently.

Are there other materials used for blower wheels, like plastics or fiberglass?

Yes, for certain applications. Plastic (polypropylene) wheels are used where extreme chemical resistance to acids is needed at low speeds and temperatures. Fiberglass Reinforced Plastic (FRP) is also used for its high corrosion resistance. However, these materials lack the strength and temperature resistance of metals for most HVAC and industrial applications.

How does material choice affect the blower wheel’s potential noise level?

Material choice has a minor direct impact on noise. The primary drivers of noise are the wheel’s aerodynamic design and its balance. However, a less rigid material like aluminum might be more prone to vibration and sympathetic resonance if not designed and balanced properly, which could contribute to noise.

Does a heavier blower wheel always use more energy?

Yes, a heavier wheel requires more energy (torque) to start spinning from a stop. Once at a constant speed, the difference in energy consumption is less significant, but in systems that start and stop frequently or use variable speed drives, a lighter aluminum wheel will typically offer better overall energy efficiency.

Can you apply coatings to galvanized steel to make it perform like stainless steel?

Specialty coatings like epoxy or phenolic coatings can significantly improve the chemical resistance of a galvanized steel wheel, making it a viable, lower-cost alternative in some moderately corrosive environments. However, these coatings do not typically increase the wheel’s temperature resistance and can be damaged by abrasion, whereas stainless steel’s properties are inherent to the metal itself.

For a standard residential furnace, which material is the most common and why?

Galvanized steel is by far the most common material for residential furnaces. The environment inside a furnace is relatively controlled—it’s dry and not chemically corrosive. Galvanized steel provides more than enough corrosion protection, excellent strength and durability, and is the most cost-effective option for this high-volume application.

How does the manufacturing process differ for aluminum versus stainless steel wheels?

The processes differ mainly in forming and joining. Aluminum is softer and easier to form but requires specialized welding techniques (TIG/MIG with argon gas). Stainless steel is much harder and requires more powerful machinery to stamp and form. While it can be welded more traditionally, its hardness makes the entire process more demanding on tooling and equipment.

Conclusion: Making the Right Material Choice with an Expert Partner

As we’ve seen, there is no single “best” blower wheel material. The right choice is a careful balance of engineering requirements and budget. Galvanized steel provides an unbeatable value for general use, aluminum offers unique benefits for weight-sensitive and humid applications, and stainless steel stands alone as the necessary solution for the most extreme environments.

But choosing the right material is just the first step. Turning that raw material into a perfectly formed, dynamically balanced, and aerodynamically efficient blower wheel requires deep manufacturing expertise. The subtle differences in how these metals are stamped, riveted, and welded can make all the difference in the final component’s performance and reliability.

At TSLBlower, we don’t just supply parts; we engineer complete airflow solutions. With over 20 years of specialized experience, our engineers can guide you through the complexities of material selection, design a fully custom wheel tailored to your specific environment, and leverage our flexible, zero-MOQ manufacturing to deliver. Don’t let a material challenge compromise your system’s integrity. Contact TSLBlower today to discuss your project and get an expert quote within 24 hours.