Picture this: a state-of-the-art chemical processing plant, meticulously designed for safety and efficiency. Suddenly, an alarm blares. A critical ventilation fan has failed, not because of a mechanical fault, but because it was silently eaten away from the inside. The standard steel blower wheel, a powerhouse in any normal HVAC system, stood no chance against the invisible onslaught of acidic fumes. This failure isn’t just an expensive inconvenience; it’s a critical safety breach, halting production and putting personnel at risk. This scenario is far too common and highlights a crucial, often overlooked, aspect of industrial design: not all air is created equal. When your environment is laced with chemicals, salts, or moisture, selecting a blower wheel isn’t just about airflow and pressure—it’s about chemical survival.

To select the right blower wheel for a corrosive environment, you must first identify the specific chemical agents, their concentrations, and the operating temperature. This data allows you to choose a base material, like 316L stainless steel or polypropylene, or a specialized coating that offers proven resistance to that specific chemical profile, ensuring long-term structural integrity and safe, reliable performance.

The standard-issue blower wheel is an engineering marvel, but in the wrong setting, it’s a ticking time bomb. The real challenge isn’t just picking a “stronger” material; it’s a game of chemical chess. You need to anticipate how your specific environment will attack the fan and choose a material that can withstand that attack day in and day out. Will a robust stainless steel suffice, or do you need the inert properties of a specialized polymer? Is a protective coating a cost-effective solution or a risky gamble? In this guide, we will walk you through the essential steps to make an informed decision, ensuring your air-moving system is not just a component, but a fortress.

Table of Contents

ToggleWhat Defines a “Corrosive Environment” and Why is it a Critical Factor for Blower Wheels?

A corrosive environment is any setting where the air contains chemical agents—such as acids, salts, or even high humidity—that actively degrade and destroy standard materials like carbon steel. This factor is critical for blower wheels because corrosion directly compromises the wheel’s structural integrity. This can lead to dangerous imbalances, reduced performance, and ultimately, catastrophic failure, posing severe safety risks and causing costly operational downtime in chemically aggressive airstreams.

Beyond Just “Bad Air”

When we talk about a “corrosive environment,” we’re moving beyond simple dust or dirt in the air. We’re entering a realm where the air itself is an attacker. A blower wheel is a high-stress, high-velocity component. It’s precision-balanced to spin at thousands of revolutions per minute. Even a tiny amount of material loss from corrosion can throw that balance off, leading to a cascade of problems. Understanding the enemy is the first step to defeating it.

The Usual Suspects: A Lineup of Chemical Aggressors

Corrosion isn’t a single entity; it’s a team of aggressors, each with a preferred method of attack. Identifying which ones are present in your airstream is the most important piece of the puzzle.

- Acids: These are some of the most aggressive agents. From sulfuric acid fumes in battery charging rooms to hydrochloric acid in chemical processing, acids rapidly eat away at most common metals, including standard steel and even some grades of aluminum.

- Alkalis (Bases): While often thought of as the opposite of acids, strong alkalis like sodium hydroxide or potassium hydroxide can be just as destructive, particularly to aluminum and other amphoteric metals.

- Solvents: Organic solvents found in painting booths, pharmaceutical manufacturing, or cleaning processes can attack not just metals, but also plastics and coatings, causing them to soften, swell, or dissolve.

- Salts and Saline Moisture: Think coastal areas, marine applications, or food processing plants using saline solutions. Chloride ions, in particular, are notorious for causing localized “pitting” corrosion in stainless steels, which can be even more dangerous than uniform material loss.

- General Moisture and Humidity: Never underestimate water. High humidity alone can accelerate the oxidation (rusting) of carbon steel. When combined with other pollutants like sulfur dioxide from industrial emissions, it forms weak acids, turning simple condensation into a corrosive cocktail.

The Two Amplifiers: Why Temperature and Concentration Change the Game

Identifying the chemical is only half the battle. The intensity of its attack is governed by two key factors: concentration and temperature. Ignoring them is like underestimating your opponent’s strength and speed.

- Concentration (The Strength of the Attack): It’s simple chemistry: a higher concentration of a corrosive agent means there are more destructive molecules packed into every cubic foot of air that hits the fan blade. A dilute, low-concentration fume might only cause slow, surface-level damage over years. The same chemical at a high concentration could destroy a blower wheel in weeks. It’s crucial to know not just *what* the chemical is, but *how much* of it is in the air.

- Temperature (The Speed of the Attack): Heat is a catalyst. As a general rule of thumb, for many chemical reactions, the rate of corrosion doubles for every 10°C (18°F) increase in temperature. A blower wheel operating in a 40°C environment will corrode significantly faster than the exact same wheel in a 20°C environment, even if the chemical concentration is identical. The heat energizes the corrosive molecules, making them more reactive and speeding up their destructive work.

How Does Corrosion Actually Damage a Blower Wheel and Affect System Performance?

Corrosion damages a blower wheel by physically eating away at its material through processes like uniform thinning, localized pitting, or stress-induced cracking. This material loss unbalances the precisely engineered wheel, leading to severe vibrations, reduced aerodynamic efficiency (less airflow), and ultimately, the risk of catastrophic structural failure. This compromises not only system performance but also operational safety by potentially releasing hazardous fumes.

The Anatomy of Failure – Three Faces of Corrosion

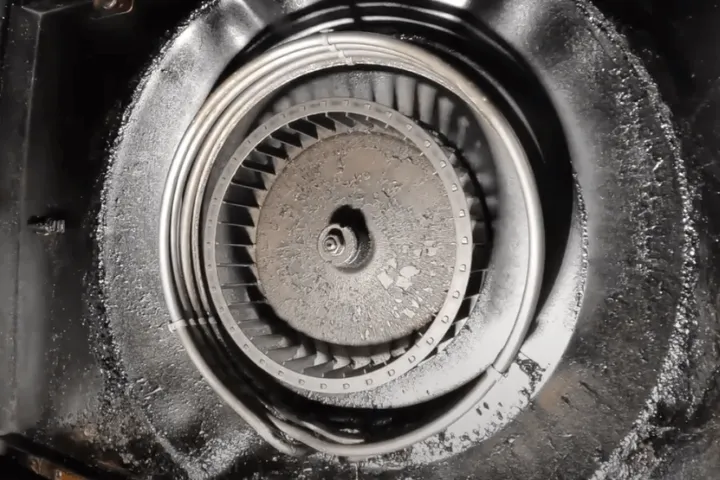

Corrosion isn’t just a cosmetic issue like rust on a garden fence; on a high-performance blower wheel, it’s a structural disease. The damage it inflicts is insidious and can manifest in several ways, each with its own unique danger profile. Understanding how a wheel can fail is key to preventing it.

A. Uniform Attack: The Slow and Steady Burn

This is the most straightforward type of corrosion. Imagine the entire surface of the blower wheel slowly and evenly dissolving, like a sugar cube in water. It’s often characterized by a general rusting or tarnishing of the surface. While it looks bad, its primary danger is the gradual thinning of the material. Over time, the blades and backplate become weaker, less able to handle the immense centrifugal forces of rotation. It’s a predictable failure mode, but if left unchecked, it will inevitably lead to structural collapse.

B. Pitting Corrosion: The Insidious Assassin

Pitting is far more dangerous than uniform corrosion. Think of it like a cavity in a tooth. From the outside, you might only see a tiny pinhole, but underneath, a deep pit is forming. This localized attack, often triggered by chloride ions (from salts), drills deep into the metal. A blade can look perfectly fine during a quick visual inspection, yet be riddled with internal pits that have compromised more than 50% of its thickness. Because it’s so concentrated, pitting can perforate a blade or hub with surprising speed, creating a point of weakness that can initiate a crack and lead to sudden failure.

C. Stress Corrosion Cracking (SCC): The Silent Killer

SCC is arguably the most feared mode of failure. It is a deadly trifecta requiring three conditions simultaneously:

- A susceptible material (like certain stainless steels).

- A specific corrosive agent (e.g., chlorides or caustics).

- Tensile stress (which is always present in a rotating blower wheel).

When all three are present, microscopic cracks can form and propagate through the material with no obvious signs of corrosion. The wheel might look completely intact, yet be riddled with internal fissures. Failure from SCC is often sudden, unexpected, and catastrophic, occurring without any of the usual warning signs like vibration or noise. It’s a silent killer that makes material selection in high-stress, specific chemical environments absolutely critical.

The Domino Effect: From a Speck of Rust to System-Wide Failure

The physical damage to the wheel is just the beginning. It sets off a chain reaction that ripples through the entire ventilation system, compromising performance and safety at every step.

- 1. Material Degradation & Imbalance: It starts here. A blower wheel is balanced to a tolerance of mere grams. When corrosion eats away even a small, uneven amount of material, it’s like taping a weight to one side of your car’s tire. This creates a significant imbalance.

- 2. Severe Vibration & Noise: The imbalance immediately translates into vibration. At high RPMs, this vibration is violent. It shakes the fan housing, the motor, and the ductwork. This is often the first audible and tangible sign that something is critically wrong.

- 3. Bearing and Motor Failure: Bearings are not designed to handle these intense vibrational loads. They will wear out and fail prematurely. The vibration also puts immense strain on the motor shaft and windings, leading to costly secondary failures.

- 4. Reduced Airflow: A corroded blade is not a smooth, efficient blade. The roughened surface disrupts the carefully designed aerodynamics, creating turbulence and drag. This means the fan has to work harder to move less air, leading to a drop in system performance and an increase in energy consumption.

- 5. Catastrophic Wheel Failure: This is the endgame. The combination of material weakness and intense vibrational stress eventually exceeds the wheel’s structural limits. The wheel can disintegrate during operation, sending high-velocity metal fragments (shrapnel) down the ductwork, capable of damaging other equipment and creating a severe safety hazard.

Which Materials Are Best Suited for Resisting Chemical Attack?

The best material depends entirely on the specific chemical aggressors and temperature. For general chemical resistance and high strength, 316L stainless steel is a top choice. And for broad resistance to acids and alkalis at moderate temperatures, plastics like polypropylene (PP) offer excellent value. For extreme conditions, specialty alloys or composites like Fiberglass Reinforced Plastic (FRP) are required. A detailed chemical compatibility check is always necessary for the final selection.

Choosing Your Champion – A Material Showdown

Selecting a material for a corrosive environment is a strategic decision, balancing chemical resistance, mechanical strength, temperature tolerance, and cost. There is no single “best” material, only the “right” material for your specific application. Let’s break down the top contenders in two main categories: metals and plastics.

The Metal Contenders: Strength Under Fire

Metals are the traditional choice for blower wheels due to their high strength, rigidity, and ability to handle high temperatures. However, not all metals are created equal in a chemical fight.

- Stainless Steel (The Workhorse): This is often the first material that comes to mind. But “stainless steel” is a family of alloys.

- Type 304 SS: This is your general-purpose stainless steel. It offers good resistance to oxidation and many mild corrosives. It’s a solid, cost-effective upgrade from standard steel for general-purpose washdown areas or high-humidity environments.

- Type 316/316L SS: This is the hero for more serious chemical applications. The key difference is the addition of molybdenum. This element provides superior resistance to chlorides (salts) and a wider range of acids. 316L (the “L” stands for “Low Carbon”) is preferred for welded fabrications as it reduces the risk of corrosion at the weld seams. It’s the go-to choice for food processing, pharmaceutical, and marine applications.

- Aluminum (The Lightweight): Aluminum is lightweight and naturally forms a protective oxide layer, giving it good resistance in pH-neutral or mildly acidic environments. However, it’s highly vulnerable to both strong alkalis (like sodium hydroxide) and certain strong acids. Its lower melting point also limits its use in high-temperature applications.

- Special Alloys (The Elite Guard): For the most extreme environments—think high-concentration, high-temperature acids—you need to call in the special forces. Alloys like Hastelloy® or Inconel® offer incredible resistance across a vast spectrum of chemicals and temperatures. They are the ultimate solution but come with a significantly higher price tag, reserved for applications where nothing else will survive.

The Polymer & Composite Champions: Chemical Inertness

Plastics and composites have become major players in corrosive air handling. While they generally have lower temperature limits and mechanical strength than metals, their chemical inertness is often superior, especially against complex acid and alkali mixtures.

- Polypropylene (PP) (The All-Rounder): PP is a fantastic, cost-effective choice for a huge range of corrosive applications. It boasts excellent resistance to a wide variety of acids, alkalis, and solvents. It’s lightweight and easy to fabricate. Its main limitation is temperature; it typically shouldn’t be used in applications exceeding 80-90°C (180-190°F).

- Polyvinyl Chloride (PVC) (The Specialist): Similar to PP, PVC offers great chemical resistance. It’s particularly well-suited for handling strong acids like sulfuric and nitric acid. However, it can be more brittle than polypropylene and has a slightly lower maximum service temperature. It’s often used in fume hoods and chemical plating exhaust systems.

- Fiberglass Reinforced Plastic (FRP) (The Hybrid): FRP is a composite material, not a simple plastic. It combines the exceptional chemical resistance of a specific resin (like vinyl ester or polyester) with the strength of embedded glass fibers. This creates a material that is both incredibly corrosion-resistant and structurally robust, bridging the gap between plastics and metals. FRP fans can be built to large sizes and handle significant pressures, making them ideal for large-scale industrial scrubbers, wastewater treatment plants, and pulp and paper mills.

Are Protective Coatings a Viable Alternative to Corrosion-Resistant Base Materials?

Yes, protective coatings are a viable and often cost-effective alternative, especially for mild to moderate corrosive environments. A high-performance coating like epoxy or phenolic can create a durable barrier between a standard steel wheel and the corrosive airstream. However, their reliability depends entirely on flawless application and the risk of physical damage. For highly aggressive chemicals or abrasive conditions, a solid corrosion-resistant alloy or composite material remains the safer choice.

The Armor Strategy – To Coat or Not to Coat?

Think of this decision as choosing between a soldier wearing solid plate armor versus one wearing a high-tech, bulletproof vest. The solid armor (a 316L stainless steel wheel) is inherently tough all the way through. The vest (a coated carbon steel wheel) relies on its specialized outer layer for protection. Both can be effective, but their strengths and weaknesses are very different. A coating strategy can be brilliant, but it’s a calculated risk that requires a clear understanding of the trade-offs.

The Pros: Why Coatings Can Be a Smart Move

- Cost-Effectiveness: This is the biggest advantage. Coating a standard carbon steel wheel is almost always significantly cheaper than fabricating a wheel from a solid block of 316L stainless steel or a specialty alloy. For projects with tight budgets, coatings can make corrosion protection accessible.

- Versatility: There is a vast array of specialized coatings available, each formulated to resist specific chemicals. This allows you to “tune” the protection to your environment without having to source an exotic base material.

- Maintaining Mechanical Strength: A coated carbon steel wheel retains the inherent strength, rigidity, and temperature tolerance of steel. This can be an advantage over plastic fans in applications requiring high pressures or operating at elevated temperatures where polymers would soften.

The Cons: The Achilles’ Heel of Coatings

- The “Single Point of Failure” Risk: A coating is only as good as its weakest point. A tiny pinhole, scratch, or chip from an abrasive particle in the airstream can breach the protective barrier. Once breached, corrosion can creep in *underneath* the coating, spreading unseen until it causes significant damage.

- Application is Everything: A flawless coating requires meticulous surface preparation (sandblasting, cleaning) and expert application (correct thickness, proper curing). A poorly applied coating will peel, flake, or crack, offering little to no real protection. You are relying on the quality control of the applicator.

- Limited Lifespan: All coatings will degrade over time due to chemical exposure, UV light, and general wear and tear. They are a sacrificial layer and may require periodic inspection and re-application, adding to the long-term maintenance cost.

Does the Choice of Material Impact the Aerodynamic Design and Efficiency of the Wheel?

Yes, absolutely. The choice of material directly impacts aerodynamic design and efficiency. Weaker or heavier materials, like plastics or stainless steel, require thicker blades and more robust construction compared to standard steel. This added thickness and weight alters the blade’s aerodynamic profile, which can increase drag, reduce efficiency, and necessitate a more powerful motor to achieve the same airflow and pressure performance.

The Unseen Connection Between Material and Airflow

In a perfect world, an aerodynamicist would design a blower wheel with blades that are infinitely thin and impossibly strong to slice through the air with perfect efficiency. In the real world, we are bound by the laws of physics and material science. Every material choice is a compromise, a trade-off between chemical resistance, strength, and weight. This compromise has a direct and measurable effect on how the fan actually performs.

The Strength vs. Thickness Trade-Off: A Critical Compromise

This is the most significant factor. A material’s strength (its ability to resist bending and stress) dictates how thin a blade can be while still maintaining its shape at high rotational speeds.

- Stronger Materials (e.g., Carbon Steel, Stainless Steel): These materials have high tensile strength, allowing for the fabrication of thin, precise, and aerodynamically optimized blade profiles. Thin blades have a sharp leading edge that cuts through the air cleanly, minimizing turbulence and maximizing efficiency.

- Weaker Materials (e.g., Polypropylene, PVC): Plastics are not as rigid as metals. To prevent a plastic blade from flexing, bending, or deforming under the immense forces of rotation, it must be made significantly thicker. This thicker, blunter blade profile is less aerodynamically efficient. It creates more drag and turbulence as it moves through the air, essentially “plowing” through it rather than slicing.

The Weight Penalty: Mass, Inertia, and Motor Sizing

The density of the chosen material also plays a crucial role. A wheel fabricated from 316L stainless steel will be considerably heavier than an identical wheel made from aluminum or polypropylene.

- Increased Rotational Inertia: A heavier wheel has more inertia, meaning it requires more energy (torque) to get it spinning and to stop it. This often necessitates a larger, more powerful motor with a higher starting torque, which increases both the initial cost and the energy consumption during startup.

- Increased Structural Stress: The higher weight puts more strain on the entire assembly, including the hub, the shaft, and especially the motor bearings. This must be accounted for in the design to ensure long-term mechanical reliability.

What is the Step-by-Step Process for Correctly Specifying a Fan for a Corrosive Application?

The correct process is a systematic investigation. First, you must meticulously document all chemical agents, their concentrations, and the full operating temperature range. Next, use this data to consult chemical resistance charts and select a suitable material or coating. Finally, define your required aerodynamic performance (airflow and pressure) and select a fan model built from your chosen material that meets this duty point efficiently and safely.

Your Specification Checklist – From Theory to Purchase Order

We’ve covered the dangers, the materials, and the hidden performance trade-offs. Now, let’s put it all together into a practical, actionable checklist. Following this process methodically will take the guesswork out of your decision and ensure you are specifying a fan that is both safe and effective. Think of yourself as a detective building a case; you need to gather all the evidence before you can identify the right solution.

Step 1: Profile the Chemical Environment (The “What”)

This is the most critical phase. Incomplete or inaccurate information here will undermine the entire process. Be thorough.

- Identify Every Chemical Agent: What specific chemicals, fumes, or vapors will be in the airstream? Don’t generalize. “Acid fumes” is not enough; you need to know if it’s “98% sulfuric acid” or “10% hydrochloric acid.”

- Determine Concentrations: What is the concentration of each chemical, usually measured in Parts Per Million (PPM) or as a percentage? Is it constant or does it fluctuate?

- Look for Abrasives: Is there any particulate matter or dust in the airstream? Even non-corrosive dust can be abrasive and can scratch or erode a protective coating, creating a point of failure.

Step 2: Profile the Operational Conditions (The “How”)

Chemicals don’t act in a vacuum. The operating conditions dramatically influence their behavior.

- Define the Temperature Range: What is the minimum, normal, and maximum operating temperature of the air? Remember, heat accelerates corrosion. A material safe at 20°C might fail at 80°C.

- Note the Presence of Moisture: What is the humidity level? Is there a risk of condensation forming on the fan wheel? Moisture can activate dormant chemicals and create new corrosive compounds.

Step 3: Select the Material (The “Defense”)

With your evidence gathered, you can now consult the experts—in this case, chemical resistance charts and material specialists.

- Consult Chemical Resistance Charts: Use your data from Steps 1 & 2 to cross-reference against reliable chemical compatibility charts. These charts will give materials a rating (e.g., A=Excellent, B=Good, C=Fair, D=Severe Effect) for specific chemicals at specific temperatures.

- Shortlist Potential Candidates: Based on the charts, create a shortlist of materials (e.g., 316L SS, Polypropylene, FRP) or coatings (e.g., Phenolic) that show excellent resistance to your entire chemical profile.

- Make the Final Choice: Weigh the pros and cons of your shortlisted candidates based on cost, mechanical strength, and the risk tolerance of the application.

Step 4: Define the Aerodynamic Duty (The “Job”)

Now that you know what the fan needs to be made of, you can define what it needs to do.

- Determine Required Airflow (CFM): How much air needs to be moved to effectively ventilate the space or process?

- Calculate System Static Pressure (SP): What is the total resistance of the system (ductwork, filters, hoods, scrubbers) that the fan must overcome?

- Specify the Duty Point: Combine these two values into a single duty point (e.g., “1,500 CFM at 2.5 inches SP”).

Step 5: Select the Fan and Finalize the Specification

This is the final step where you bring everything together.

- Find a Fan Model: Search manufacturer catalogs for a fan model, constructed from your chosen material (from Step 3), that can meet your duty point (from Step 4) efficiently.

- Check the Performance Curve: Ensure your duty point falls within the fan’s high-efficiency range on its specific performance curve for that material.

- Provide All Data to the Manufacturer: When ordering, provide your supplier with the complete environmental and performance data. This allows them to verify your selection and ensures you receive a product that is truly fit for purpose.

Why is Partnering with an Experienced Manufacturer Crucial for Custom Corrosive Solutions?

Partnering with an experienced manufacturer is crucial because selecting a corrosion-resistant fan involves complex trade-offs between material science, aerodynamics, and safety. An expert partner like TSLBlower provides invaluable guidance on material selection, offers custom fabrication capabilities to meet unique challenges, and ensures the final product is certified to perform safely and reliably in your specific hazardous environment, preventing costly and dangerous failures.

Dive Deeper: Beyond the Catalog – The Value of True Expertise

You can follow a checklist perfectly and read every chemical resistance chart available, but there is no substitute for decades of hands-on experience. The most challenging corrosive environments often live in the gray areas where standard charts don’t apply or where multiple factors create a unique chemical cocktail. This is where a partnership with a specialized manufacturer transitions from a simple purchase to a critical investment in safety and reliability.

A. Guidance Through the Maze of Material Science

The sheer number of available materials and coatings can be overwhelming. An experienced manufacturer has seen what works and, more importantly, what fails in the real world.

- Nuanced Knowledge: They understand the subtle differences. They know that while 316L stainless steel is great for chlorides, it might be susceptible to stress corrosion cracking in a specific temperature range. They know which epoxy coating holds up to solvent vapors and which one will peel. This knowledge, built from thousands of applications, goes far beyond what a simple datasheet can tell you.

- Risk Assessment: They can help you perform a proper risk-reward analysis. Based on your application’s criticality, they can advise whether the cost savings of a coated wheel is a smart move or an unacceptable gamble, guiding you toward the solution with the best long-term value and safety profile.

B. Custom Fabrication for Unique Challenges

Corrosive environments rarely conform to standard sizes and shapes. Off-the-shelf solutions often fall short. A true manufacturing partner doesn’t just sell you what’s in their catalog; they build what you need.

- Bespoke Design: Need a fan made from a special alloy with a unique housing to fit into a tight space? An experienced manufacturer with in-house R&D and molding capabilities can design and build a completely custom solution from the ground up.

- Specialized Welding and Fabrication: Working with materials like 316L stainless steel or fabricating FRP requires specialized techniques. Proper welding procedures for stainless steel are critical to maintain corrosion resistance at the seams. Fabricating FRP is an art form. A seasoned manufacturer has the certified welders and skilled technicians to ensure the quality of every joint and seam.

C. Certified Performance and Peace of Mind

When you buy a fan for a hazardous environment, you are buying a promise of safety and performance. An established manufacturer backs up that promise with proof.

- Guaranteed Performance: They can provide you with certified performance curves for the exact material you are buying, so you know the fan will deliver the required airflow and pressure. There’s no de-rating or guesswork involved.

- Quality Control and Traceability: From raw material sourcing to final balancing and testing, a quality-focused manufacturer maintains rigorous QC at every step. They can provide material certifications (like MTRs for steel) and documentation proving the fan was built to specification.

- Regulatory Compliance: They understand the standards. Whether it’s meeting specific safety regulations for explosive atmospheres or holding international certifications like UL, CE, and RoHS, a professional partner ensures your component helps your final product meet its own regulatory demands.

Don’t Gamble with Corrosive Environments. Engineer a Solution.

Selecting the right blower wheel for a corrosive application is one of the most critical decisions you can make for the safety and efficiency of your operations. The cost of failure—in downtime, repairs, and potential hazards—far outweighs the investment in getting it right the first time.

With over two decades of specialized experience, TSLBlower is your trusted partner in navigating these challenges. We combine deep material expertise with state-of-the-art manufacturing to deliver robust, reliable, and custom-tailored blower wheel solutions.

- Expert Consultation: Let our engineers analyze your specific chemical profile and recommend the optimal material or coating.

- Custom Fabrication: From 316L Stainless Steel to Polypropylene and FRP, we build what your environment demands.

- No Minimum Orders: Whether you need a single replacement prototype or a full production run, our zero-MOQ policy supports your project at every scale.

Protect your investment and ensure operational safety. Let’s build a solution that lasts.

Contact TSLBlower Today for a Custom Quote & Material Consultation