In food processing or industrial drying, a standard blower wheel isn’t just inefficient—it’s a liability. Indeed, the risks of corrosion, contamination, and heat-induced failure can halt production and compromise product safety. The airflow component you choose must be as robust as the environment it operates in.

To select a blower wheel for harsh environments, you must prioritize materials like 304/316 stainless steel for its resistance to heat and corrosion. In addition, you must specify robust, easy-to-clean designs, such as continuously welded blades, ensure the wheel undergoes high-temperature balancing, and verify its compliance with relevant hygienic or safety standards.

This decision goes far beyond simple sizing and specifications. Ultimately, it demands a deeper understanding of material science and mechanical design. This guide will walk you through the critical factors, from material selection to construction techniques, empowering you to specify a blower wheel that will not just survive, but thrive in your most challenging applications.

Table of Contents

ToggleWhat Defines a “Harsh Environment” for a Blower Wheel?

A “harsh environment” for a blower wheel is any setting that subjects the component to extreme conditions that would cause a standard, general-purpose wheel to fail prematurely. Specifically, these conditions typically include continuous high temperatures, corrosive chemical or moisture exposure, strict hygienic requirements, or the presence of abrasive particulates.

Before you can choose the right solution, you must first understand the specific nature of the problem. For instance, a blower wheel inside a commercial convection oven faces a different set of challenges than one in a chemical washdown area. Let’s break down the primary types of harsh environments.

The Challenge of Continuous Extreme Temperatures

Many industrial processes, from drying and curing to baking and sterilizing, involve very high temperatures. For this reason, a standard galvanized steel wheel may begin to fail at temperatures above 400°F (200°C). At such elevated temperatures, metals can lose their tensile strength, which in turn leads to blade deformation or “creep” under centrifugal force. This distortion can cause catastrophic imbalance and failure. Furthermore, repeated cycles of heating and cooling can introduce stress fractures in poorly constructed wheels.

The Threat of Corrosion from Moisture and Chemicals

Corrosion is a relentless enemy in many industries. In food processing, for example, frequent washdowns with caustic cleaning agents are common. Similarly, in marine or coastal applications, salt-laden air is a constant threat. In chemical plants, acidic fumes can easily eat away at standard materials. A simple zinc coating on galvanized steel is no match for this kind of chemical attack. Consequently, corrosion weakens the material, creates surface pitting, and can cause flakes of rust to contaminate the product stream.

The Strict Requirements for Hygienic and Sanitary Conditions

In food, pharmaceutical, and medical applications, the blower wheel itself cannot be a source of contamination. The material must be non-porous and non-leaching, meaning it will not harbor bacteria or shed particles into the air. More importantly, the design must be easy to clean and sanitize. Riveted designs with overlapping seams, crevices, and sharp corners are unacceptable because they create pockets where bacteria and other contaminants can thrive, hidden from cleaning processes.

The Physical Impact of Abrasive or Combustible Dust

In environments like grain processing, woodworking, or bulk material conveying, the air is not just air—it’s filled with abrasive particles. These particles act like sandblasters, steadily eroding the blades of a blower wheel over time. This process leads to a loss of material, imbalance, and eventual failure. In some cases, the dust may also be combustible, which requires specialized “spark-resistant” designs to prevent ignition sources.

Which Materials Are Best for High-Temperature and Corrosive Applications?

Stainless steel, particularly grades 304 and 316, is the best and most common material for blower wheels in high-temperature and corrosive environments due to its inherent resistance to oxidation, heat, and chemical attack. For less severe applications, however, specialized coatings on carbon steel can offer a cost-effective alternative, while certain aluminum alloys can be used in moderate heat where low weight is also a priority.

The material you choose is your first and most important line of defense against a harsh environment. Let’s explore the top contenders.

Why Stainless Steel (304 vs. 316) is the Gold Standard

Stainless steel’s “superpower” comes from its chromium content, which forms a passive, self-healing oxide layer on the surface. This invisible shield actively protects the steel from rust and corrosion.

- 304 Stainless Steel: This is the workhorse of the stainless family. It offers excellent corrosion resistance in most environments and can handle continuous temperatures up to 1500°F (815°C). Therefore, it is ideal for most food processing, baking, and industrial drying applications.

- 316 Stainless Steel: This grade contains an added element, molybdenum, which significantly enhances its resistance to chlorides (like salt) and harsh chemicals. For this reason, it is the mandatory choice for marine applications, chemical processing, and areas with aggressive washdown protocols.

Are High-Temperature Aluminum Alloys an Option?

While standard aluminum is not suitable for high heat, certain alloys can perform in moderately hot environments, typically up to 300-400°F (150-200°C). The primary benefit of aluminum is its low weight, which reduces startup torque on the motor. However, it does not have the structural strength or heat resistance of stainless steel, making it suitable only for specific, less demanding applications.

The Strategic Role of Specialized Coatings on Steel Wheels

For applications with moderate chemical exposure where the cost of stainless steel is prohibitive, a coating can be a viable compromise. In this process, engineers can coat a base wheel made of carbon steel with materials like epoxy or phenolic resins. These coatings create a protective barrier against moisture and specific chemicals. Still, they are not a universal solution. Coatings have lower temperature limits than stainless steel and can be compromised by scratching or abrasion.

How Does Mechanical Design Impact Durability and Safety?

Beyond material choice, the mechanical design and construction of a blower wheel are critical for its performance in harsh environments. A durable design, for instance, features continuous welds instead of rivets, thicker blades to resist deformation, and smooth, crevice-free surfaces for easy cleaning. Crucially, it must also undergo high-temperature balancing to ensure stability at its intended operating temperature.

A wheel made from the best material will still fail if it is poorly constructed. Indeed, in harsh environments, design details make all the difference.

Welded vs. Riveted Construction: A Critical Choice for Longevity

In a sanitary or high-stress environment, a continuously welded design is superior to a riveted one.

Rivets and mechanical fasteners inherently create seams and crevices. In a hygienic setting, these are breeding grounds for bacteria. In a high-temperature or high-stress setting, they also act as failure points. In contrast, a fully welded construction creates a single, solid unit that is stronger, more durable, and infinitely easier to clean and sanitize.

The Importance of Blade Thickness and Shape for High-Stress Loads

A blower wheel operating at high speed and high temperature is under immense physical stress. For this reason, thicker blades provide the structural rigidity needed to prevent them from flexing, twisting, or deforming under load. The design of the blades and the supporting backplate must be engineered to handle the centrifugal forces and thermal expansion that occur at operating temperature, not just at room temperature.

Designing for Cleanability: Eliminating Crevices Where Contaminants Hide

In food and pharmaceutical applications, a “sanitary design” is paramount. This means that all surfaces must be smooth and easily accessible for cleaning. It involves eliminating sharp corners, overlapping seams, and any feature that could trap product or microorganisms. This often requires custom designs with polished welds and radiused corners to ensure the wheel can be made verifiably clean.

The Science of High-Temperature Balancing: Why Standard Balancing Fails

Engineers typically balance a wheel at room temperature. However, when that wheel heats up to several hundred degrees, the metal expands. If this thermal expansion is not perfectly uniform, the process can unbalance the wheel at its operating temperature, leading to vibration and premature bearing failure. As a result, true high-temperature applications require a specialized balancing process that accounts for these changes to ensure the wheel runs smoothly when it’s hot.

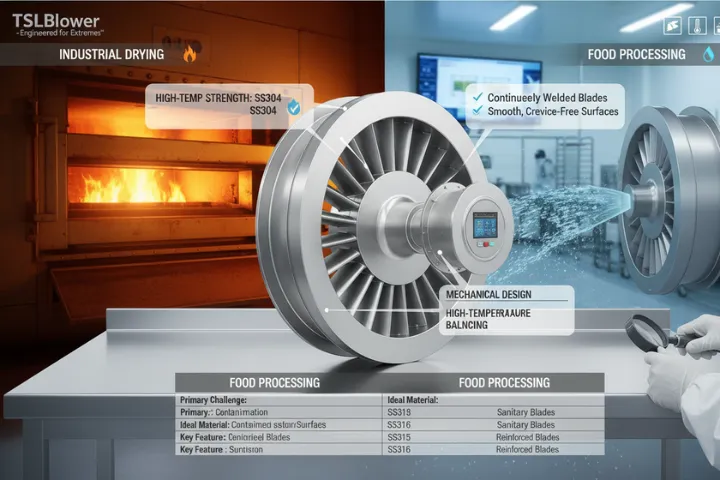

What Are the Specific Requirements for Food Processing vs. Industrial Drying?

While both are harsh environments, food processing applications prioritize hygienic design and corrosion resistance to cleaning agents, often requiring 316 stainless steel and sanitary welds. In contrast, industrial drying applications prioritize high-temperature strength and resistance to thermal fatigue, often using 304 stainless steel with robust, reinforced blade designs.

The table below breaks down the key differences in requirements for these two common applications.

| Factor | Food Processing Application | Industrial Drying Application |

|---|---|---|

| Primary Challenge | Bacterial contamination; corrosion from chemical washdowns. | Structural fatigue from high heat; abrasion from particulates. |

| Ideal Material | Stainless Steel 316 (for washdowns) or 304. | Stainless Steel 304 or other high-temp alloys. |

| Key Design Feature | Continuous sanitary welds; no crevices; polished surfaces. | Reinforced, thicker blades; high-temperature balancing. |

| Relevant Standard | NSF/ANSI standards for food contact surfaces. | Material temperature rating; spark-resistance if needed. |

Frequently Asked Questions (FAQ)

What is the difference between 304 and 316 stainless steel for a blower wheel?

Both grades are highly resistant to corrosion and heat. The key difference, however, is that 316 stainless steel includes molybdenum. This element gives it superior resistance to chlorides, salts, and harsh industrial chemicals. Therefore, you should choose 304 for general high-heat and food applications, but upgrade to 316 if the wheel will be exposed to salt or aggressive chemical cleaning agents.

Can a galvanized steel blower wheel be used in a commercial oven?

We do not recommend using galvanized steel in high-temperature commercial ovens. The zinc coating can start to degrade at temperatures above 400°F (200°C), which compromises its corrosion protection and can potentially cause flaking. For this application, stainless steel is the industry standard due to its superior heat resistance.

What does “food grade” mean for a blower component?

“Food grade” means a material is safe for contact with food products because it will not leach harmful substances. For a blower wheel, this term also implies a sanitary design. Specifically, the component must be non-porous, smooth, and free of crevices where bacteria could grow, making it easy to clean and sanitize effectively.

How does high heat affect a blower wheel’s balance over time?

High heat causes metal to expand. If engineers do not design and balance a wheel properly, this thermal expansion can cause it to become unbalanced at operating temperature, which in turn leads to vibration. Over many heating and cooling cycles, this stress can also lead to metal fatigue and cracks, permanently affecting the balance.

Are there special maintenance requirements for blower wheels in corrosive environments?

Yes, regular inspection is key. You should check for any signs of pitting or degradation. In washdown environments, furthermore, it’s critical to ensure cleaning agents are rinsed off properly. Letting them dry on the surface can sometimes accelerate corrosion, even on stainless steel.

What is an “ATEX rated” fan and when is it necessary?

ATEX refers to European directives for equipment intended for use in potentially explosive atmospheres (e.g., from combustible dust or flammable gases). An ATEX-rated fan uses spark-resistant construction—often using non-ferrous materials like aluminum for certain components—to prevent mechanical sparks that could cause an explosion. Consequently, it is necessary in environments like grain mills, chemical plants, or fine powder processing.

How do you clean and sanitize a stainless steel blower wheel?

You should clean stainless steel wheels with detergents and sanitizers that are compatible with the material. Above all, avoid using steel wool or carbon steel brushes, as these can leave particles behind that can cause rusting. Instead, use nylon brushes and follow your industry’s specific cleaning and sanitation protocols.

Conclusion: From Standard Parts to Engineered Solutions

As we have seen, selecting a blower wheel for a harsh environment is a complex engineering decision. Success requires a holistic approach that considers both the advanced material science and the robust mechanical design. The right choice is rarely found on a standard parts shelf; it must be purpose-built for the specific challenges of heat, corrosion, and sanitation.

Using a standard, off-the-shelf blower wheel in these critical applications is a significant risk. In fact, it becomes the weakest link in your process, a potential source of contamination, failure, and costly downtime. You don’t just need a part; you need a fully engineered and reliable solution that protects your process, your product, and your reputation.

At TSLBlower, we specialize in engineering and manufacturing blower wheels for the most challenging industrial environments. Whether you need a high-temperature wheel for an industrial dryer or a fully custom, food-grade stainless steel impeller with a sanitary design, our team has the expertise to design, build, and deliver. Don’t compromise on this critical component. Contact us to discuss your harsh environment application and get a quote for a blower wheel that is truly built to last.